INTRODUCTION

Case King CK25

3 Step quick set-up | ||

1. Choose box type | 2. Input carton information | 3. One button setting |

Introduction The Case King model. CK25 is one of the most advanced box making machine available today. It is designed to solve the problem of small and medium orders of corrugated boxes quickly and easily. All tools are controlled through the simple touch screen. Size change from one style and size of box to another in seconds. Whether you need to produce small gift boxes, large wraps, furniture box, or more complicated boxes, the Case King can make them all at the touch of a button. | ||

Function

Application:for carton manufacturer. Advantages:this machine is PLC+HMI control, can finish auto feed, slot, cross score, angle cut, trim, H-cut, die-cut in one time pass. Special H-slot&score structure, can do small, medium and oversize carton. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency, it is a effective solution for small quantity order. | Easy operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. |

SPECIFICATIONS

No. | Model | CK25 | CaseKing |

1 | Max. Feeding size (WxL) | 2500mm x unlimited | horizontal slotting, max length can be unlimited |

2 | Min. feeding size (WxL) | 120 x 350mm | The min size can go through |

3 | Slotting width | 7mm | Slotting blade width |

4 | Max. slotting depth | 500mm | Slotting blade length |

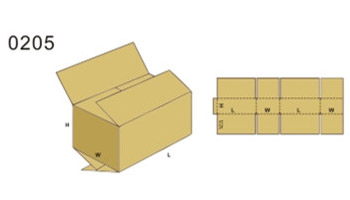

5 | 02xx Max. box height | 1600mm | Max. size between left and right slotting blade |

6 | 02xx Min. box height | 100mm | Min. Size between left and right slotting blade |

7 | Max. angle cutting width | 45mm | Angle blade length |

8 | Feeding thickness | 2-11mm | Gap between feeding rollers |

9 | Speed | 400-600pcs/h | Average speed |

10 | Air pressure | 0.3-0.6Mpa | |

11 | Total motor power | Abt. 15kW | |

12 | Dimension (WxLxH) | 3350x3700x2000mm | main machine size, if 2 unit will be less |

13 | Overall net weight | Abt6000kg | Total weight if 2 unit will be less |

Cardboard ≤ 700gsm

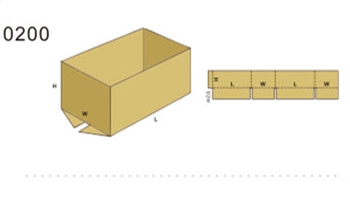

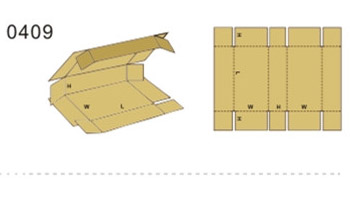

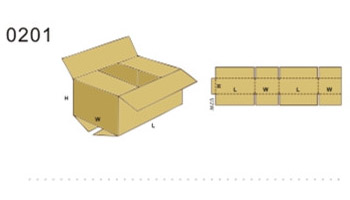

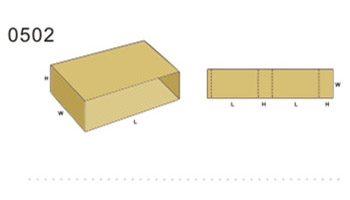

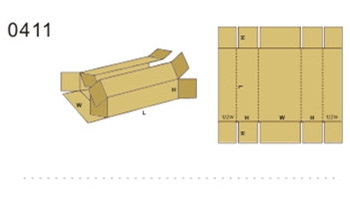

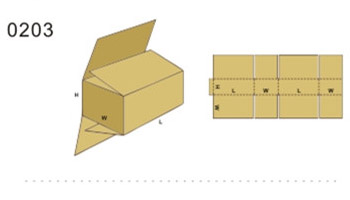

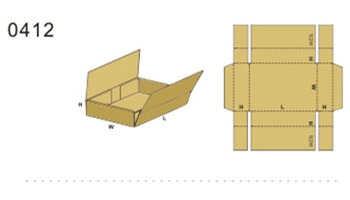

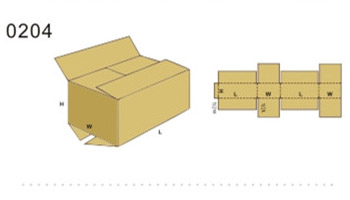

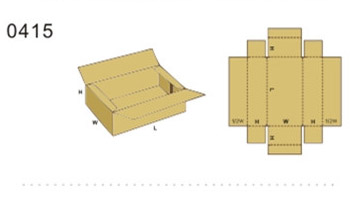

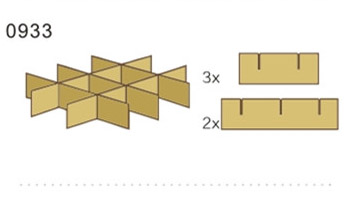

BOXES ACCORDING TO FEFCO (in one pass)

CK25 can also produce box type as follow: (without manual scorer)

● 0301,0452,0453,0911 can use 300

● 0458 can use 0302

● 0900,0902,0903 can use 0901

● 0930,0931,0932,0934,0935 can use 0933

● Define one pass:0228,0230,0231,0454,0455,0904,0905,0906,0907,0908,0909,0910,0913,0914,0920,0940,0942,0945,0946

● Define two pass:0208,0210,0212,0214,0229,0400,0403,0413,0420,0456,0921,0941,0943,0944

● Combination box:0306,0310,0312,0313,0320,0325,0331,0404,0405,0504,0505,0507,0509,0510,0512,0601,0607,0608,0610,0615,0616,0620,0621,0929

1. Are you a trading company or factory?

We are the manufacturer and also we have import export license. We have been in making die cutting machine and hot foil stamping machine since 1995.

2. Where is your company located? How can I visit there?

Our factory address: No. 11, Shuangchen Middle Road, Beichen Tech Park, Tianjin, China.

The nearest transportation center is Tianjin Binhai International Airport or Tianjin Railway Station.

3. Can you send technician for installation and training?

Yes, we can send our technician abroad for installation and training, but all the charges must be paid by buyer, such as the plane tickets (a round trip), meals, hotel, traffic etc.

4. What’s your advantages ?

--Over twenty years' experience: We have been in making die cutting machine, hot foil stamping machine and folder gluer machine since 1995.

--Customers all over the world.

--Certificate: CE certificate and GS certificate.

--Fast reply: Our team will reply you soon.

--After-sale service: We have an aftersales department, service for your problems and dealing with spare parts.

--Long-term strategic partner with Heidelberg company.

5.The price subject to Standard configurations,options need to be extra cost.

MK800FB II

·The machine drive system adopts new synchronization belt and the drive of synchronization belt wheel. The whole machine adopts the over-all steel structure and modularization design. It processes all functions. It can be installed and adjusted fast and easily. In this way, the whole machine can run steadily at a very high speed.

·HHS gluing system as option, and by installing different kinds of accessories, it can produce various kinds of boxes such as standard box, crash-lock box, mini box, injection box, CD box, inside box, fries box, 4/6 corner box.

HHS on-line inspection system as option, which help you to get zero defects.

| Data | MK800FBII |

| Applicable sheet | 200~650 g/min2 cardboard |

| Standard box -type | standard, crash-lock, double sides |

| Optional box-type | 4 corner box, 6 corner box, injection box, CE box, Inside box, Mini box |

| Max. delivery speed | 400 m/min |

| Individual adjustment paper conveying belt | 6 Groups |

| Pre-folding device | 2 Groups |

| Upper gluing device | Left: 5 mm right: 3 mm |

| Lower gluing device | 3 mm |

| Rated power | 9.22 kw |

| Air supply | 0.5~0.7 MPa,≥0.32 m3/min |

| Net weight approx. | about 5.7 t |

| Overall dimension (L×W×H) | 13,700 mm×1,870 mm×2,200 mm |

Choose the device that suits you below

(click the Picture to view more details)

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved