Function

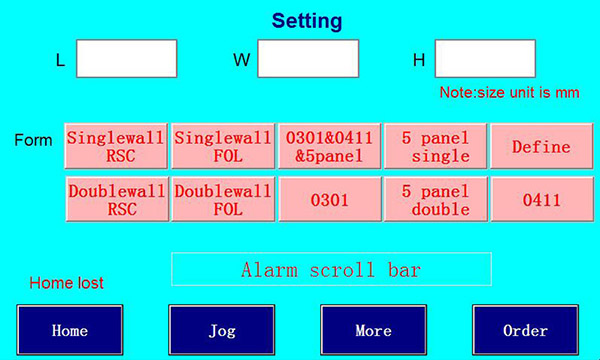

Application: for carton & cardboard manufacturer. Advantages: this machine is PLC+HMI control, can finish pre-pressing, slitting, scoring, trimming in one time pass. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency. Operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. Memory: save 300 orders | Manual feeder Auto adjusted slitter Auto adjusted pre-scorer and scorer Auto/manual blade grinder Auto adjusted pressure Jog function for fine-adjusted User-defined function Auto counter Slitting and scorer Precision ±0.5mm |

SPECIFICATIONS

No. | Model | ZBFY-AD2500 | |

1 | Blade/scorer | 4blade 6scorer | 5blade 8scorer |

2 | Feeder | Manual | |

3 | Pressure adjust | Auto | |

4 | Max. speed | 180m/min | |

5 | Max. feeding width | 2600mm | |

6 | Max. slitting width | 2500mm | |

7 | Min. slitting width | 190mm | |

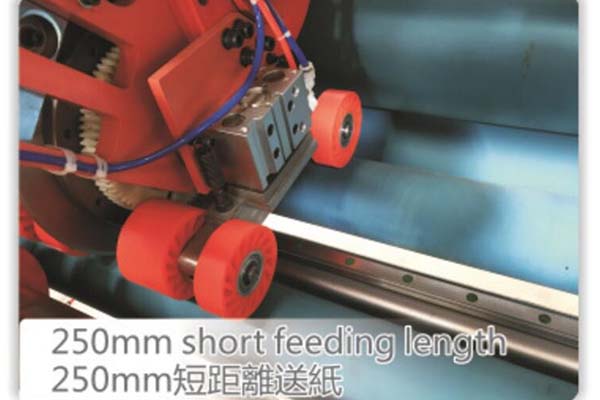

8 | Min. feeding length | 250mm (1for1: 480mm) | |

9 | Min. scoring width | 40x140mm | |

10 | Sheet thickness | 2-7mm | |

11 | Air pressure | 0.4Mpa | |

12 | Main motor power | 4kW | 5.5kW |

13 | Dimension(LxWxH) | 1570x3450x1500mm | |

14 | Overall net weight | 2500kg | 2800kg |

DESCRIBE

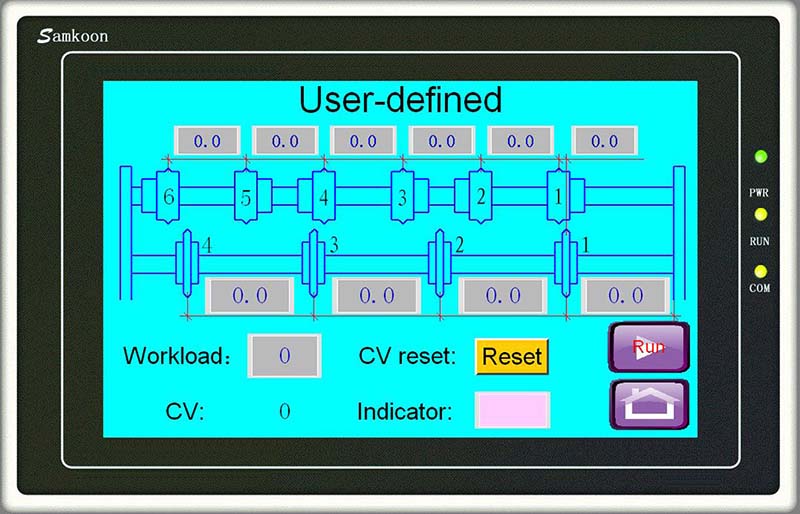

Operation HMI for Main machine

If you have some special work, can use this User-defined function

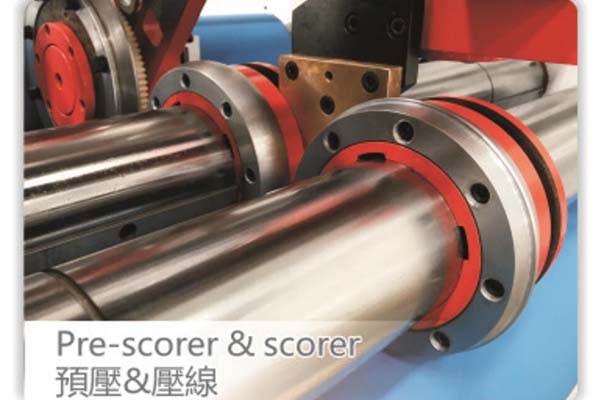

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

After-sales service

● Thanks to developed internet and after-sales network, communication become more and more convenience.

● The reliability of our machines make problem solving much easier, 99% of technical problem can be solved via remote assistance.

● Whenever customer need assistance or ask questions can communicate with the sales staff online, real-time to solve the problem, we are able to provide a full spectrum of services and prompt support.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved