Introduction The Case King model. CS25+ is a semi-auto box making machine. It cost less, very easy to operate, is it designed to help carton manufacturer to solve the problem of small quantity orders quickly and easily. This model is the best selling machine. |

Function

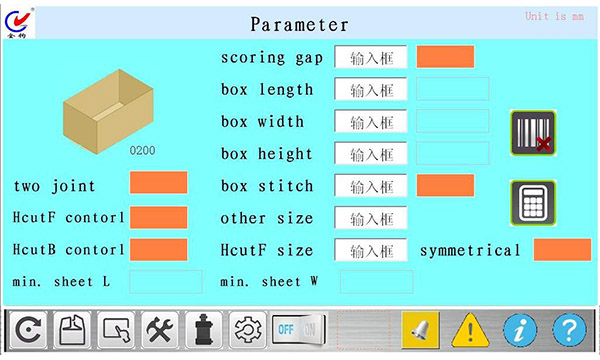

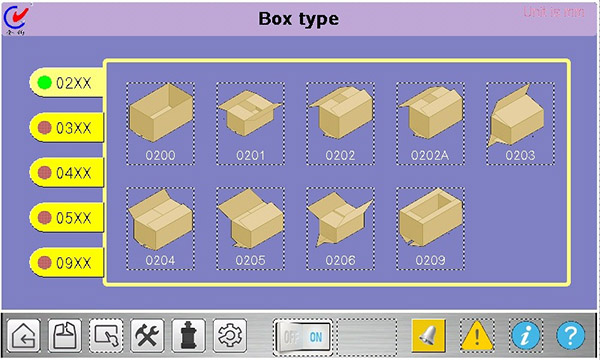

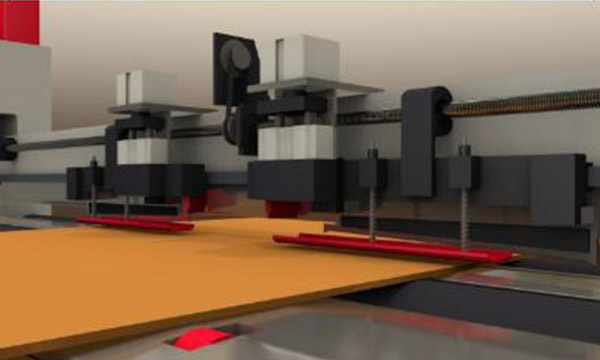

Application: for carton & cardboard manufacturer. Advantages: this machine is PLC+HMI touch screen control, can finish auto feeding, slotting, scoring, angle cutting, H-cut, v-cut, die-cut in one time pass. Special H-slot&score structure, can do small, medium and oversize carton. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency, it is a effective solution for small quality order. Easy operation: choose box type, input carton info, machine is ready to produce one carton or hundreds at the touch of a button. Both skillful operator and newcomer can control it well. Set up time: 1-30 seconds. | Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

SPECIFICATIONS

No. | Model | CS25+ | Semi auto CaseKing |

1 | Max. feeding size (WxL) | 2500mm x unlimited | horizontal slotting, max length can be unlimited |

2 | Min. feeding size (WxL) | 120 x 350mm | The min size can go through |

3 | Slotting width | 7mm | Slotting blade width |

4 | Max. slotting depth | 500/400/300mm | Slotting blade length |

5 | 02xx Max.box height | 1600/1800/2000mm | Max. size between left and right slotting blade |

6 | 02xx min box height | 70mm | Min. Size between left and right slotting blade |

7 | Max angle cutting width | 45mm | Angle blade length |

8 | Feeding thickness | 2-11mm | Gap between feeding rollers |

9 | Speed | 400-600pcs/h | Average speed |

10 | Air pressure | 0.3-0.6Mpa | |

11 | Total motor power | Abt. 15kW | |

12 | Dimension (WxLxH) | 4150x2000x1350mm | main machine size, if 2 unit will be less |

13 | Overall weight | Abt4500kg | Total weight if 2 unit will be less |

Cardboard ≤ 700gsm

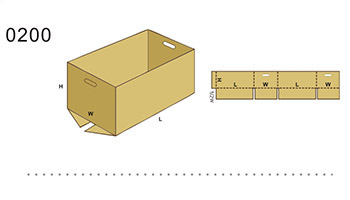

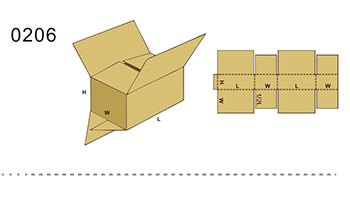

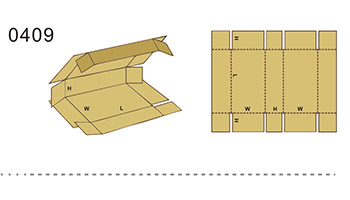

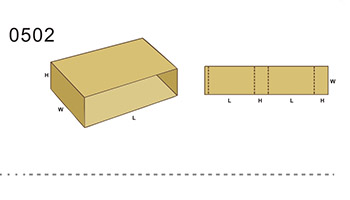

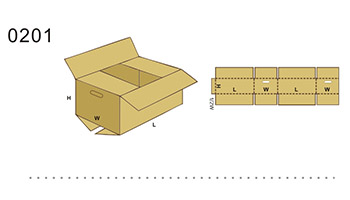

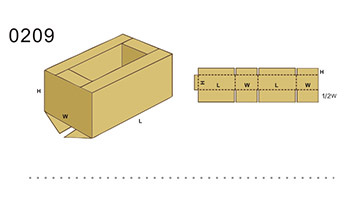

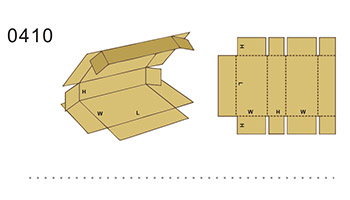

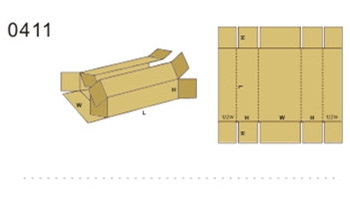

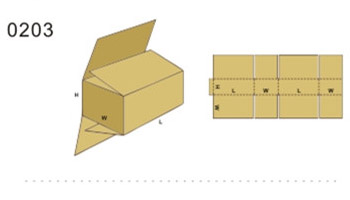

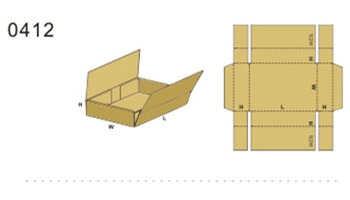

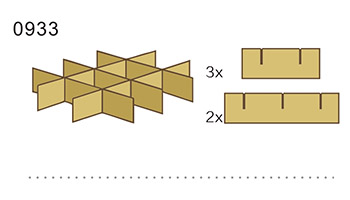

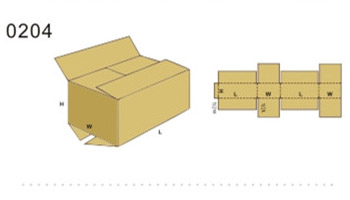

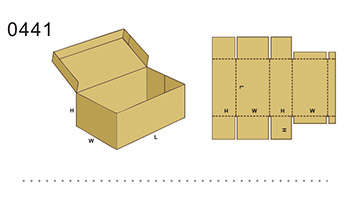

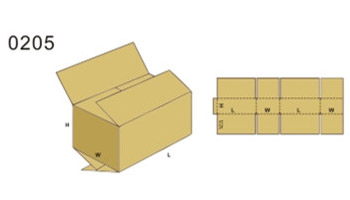

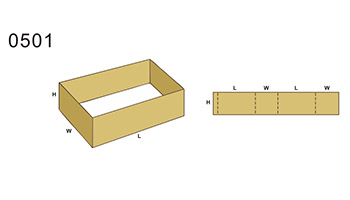

BOXES ACCORDING TO FEFCO (in one pass)

CS25+ can also produce box type as follow: (with manual scorer)

● 0301,0452,0453,0911 can use 0300

● 0458 can use 0302

● 0900,0902,0903 can us 0901

● 0930,0931,0932,0934,0935 can use 0933

● Define one pass:0214,0228,0229,0230,0231, 0403, 0413,0454,0455, 0904,0905,0906,0907,0908,0909,0910,0913,0914,0920,0940,0942,0945,0946

● Define two pass:0208,0210,0212,0400,0420,0456,0921,0941,0943,0944

● Combination box:0306,0310,0312,0313,0320,0325,0331,0404,0405,0504,0505,0507,0509,0510,0512,0601,0607,0608,0610,0615,0616,0620,0621,0929

DETAILS

(1). Operation HMI

a. 10 inch HMI |

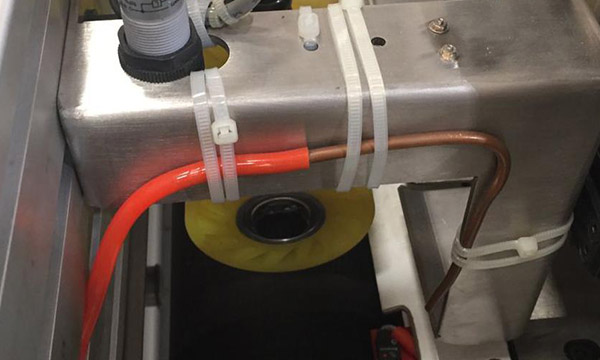

(2). Auto Feeder

a. Servo vacuum auto feeder system. |

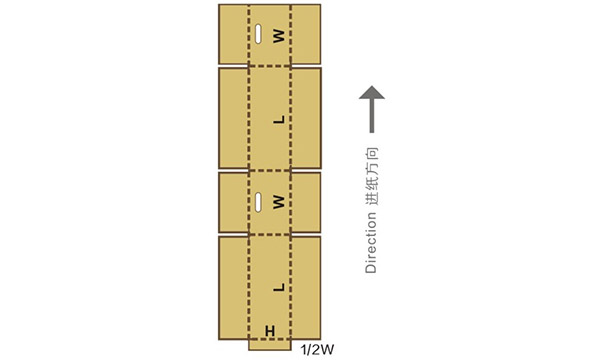

(3). H-slot&score

a. Distance between slot knives is 70-1600mm |

(4). Hcut

a. H-cut knife can cut front side, back side of cardboard sheet |

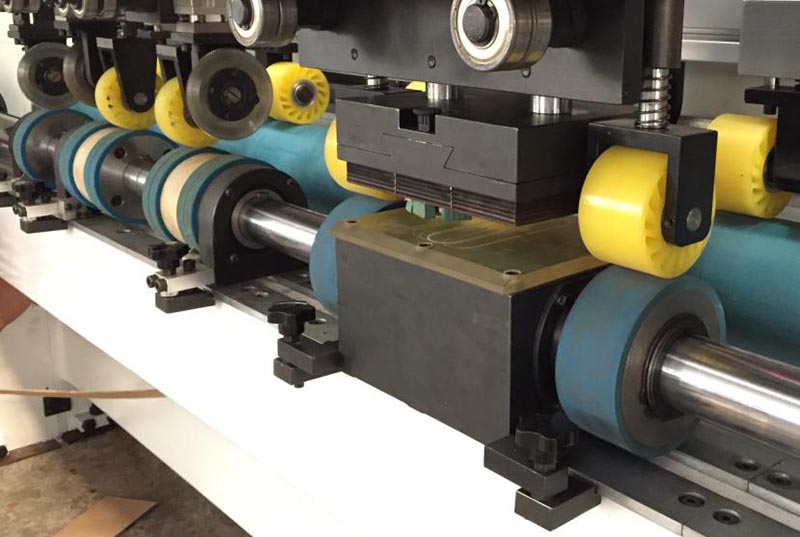

(5). V-cut & die-cut

a. 3 pcs of V-cut knife, one for trim, two for vertically cut. |

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved