Company Advantages1. Jingou Packaging Machinery corrugated cardboard cutting machine has passed comprehensive performance tests. They include durability testing, stability testing, accuracy testing, safety testing, and durability testing. Thanks to its high-speed motor, this product can quickly achieve a satisfying stacking effect

2. The product plays an important role in reducing or eliminating the amount of human work required to be finished, which helps cut labor costs. Its waste paper suction device helps maintain a clean production environment

3. Perform regular performance checks are applied to ensure high performance and reliable quality. With oxidization treatment, this product is highly rust-resistant

4. Our rigorous quality management system maintains the outstanding performance and quality of our products. Its intuitive touch screen HMI allows for easy setup and control

5. Effective QC system is carried out through the production of the product to ensure the consistent quality.

Introduction Auto feeder

Suction feeder, cardboard sheet feeding is smooth and steady. Side board is computer controlled, auto lateral adjustment. The feeder structure is simple and reliable, suitable for large quantity of production orders, easy to maintain. |

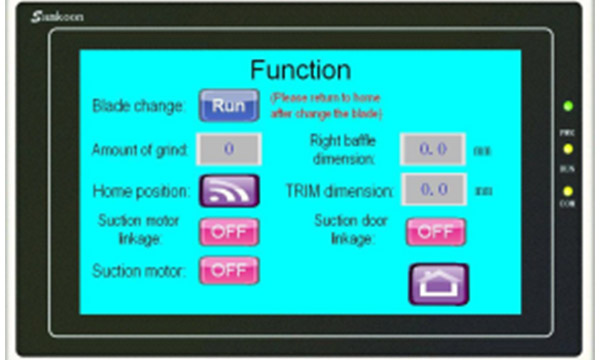

Function

Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

No. | Model | ZBFY-CD2500 | Unit |

1 | Blades & scorer | 4blade 6scorer | / |

2 | Feeder | Auto | / |

3 | Pressure adjustment | Auto | / |

4 | Speed | 160 | m/min |

5 | Max. feeding width | 2500 | mm |

6 | Max. slitting width | 2500 | mm |

7 | Min. slitting width | 200 | mm |

8 | Min. feeding length | 280 | mm |

9 | Min. scoring width | 40x140 | mm |

10 | Feeding thickness | 2-7 | mm |

11 | Air pressure | 0.4 | Mpa |

12 | Main motor power | 5.5 | kw |

13 | Dimension(LxWxH) | 2170x3450x1500 | mm |

14 | Overall net weight | Abt 3800+1500 | kg |

Cardboard ≤ 700gsm

Operation HMI for Auto feeder

Auto Thin Blade Slitter Scorer ZBFY-CD2500

● Auto feeder

● Auto adjusted slitter

● Auto adjusted pre-scorer and scorer

● Auto/manual blade grinder

● Auto adjusted pressure

● Jog function for fine-adjusted

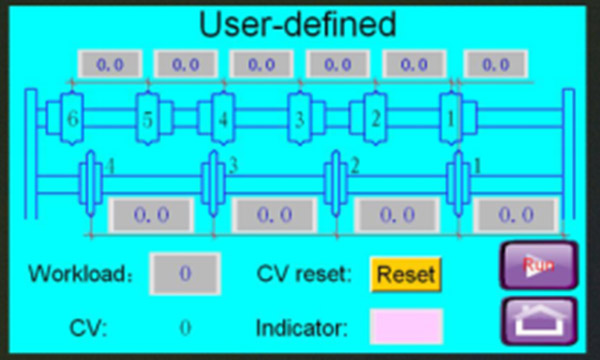

● User-defined function

● Auto counter

● Slitting and scorer Precision ±0.5mm

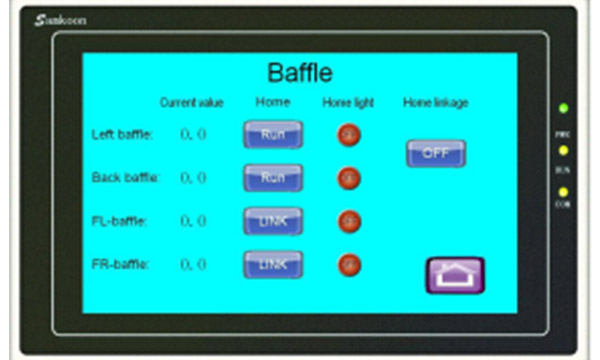

Operation HMI for Main machine

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

Company Features1. Jingou Packaging Machinery Co., Ltd. stands out among competitors relying on capacities in R&D and manufacturing. We have been highly thought of for the ability to offer corrugated cardboard cutting machine . Our factory faithfully implements the management systems of ISO 9001 and ISO 14001 to manufacture products. These ISO management systems not only guarantee the products' quality but also ensure that the products are friendly to the environment.

2. Our factory has been equipped with a wide range of production facilities. These machines can effectively ensure constant and steady production, allowing us to manufacture thousands of products within a very short time.

3. We have cultivated an in-house R&D team. They are responsible for the development of new innovative products and corporate with some famous laboratories in China. While striving to provide the most satisfying products and services, we will spare no efforts to strengthen our corporate values of integrity, diversity, excellence, collaboration and participation.