Company Advantages1. The raw materials of Jingou Packaging Machinery box machine are meticulously selected to make sure each of them works perfectly, through which the quality of the product can be ensured from the source. This product can easily achieve high-volume distribution

2. Favored by more and more customers, Jingou Packaging Machinery now has been applying the best materials and most advanced machines to produce. With oxidization treatment, this product is highly rust-resistant

3. The product is valued for its wear resistance. It has been coated with a special layer to withstand numerous times of mechanical force. Its waste paper suction device helps maintain a clean production environment

4. The product features a huge reversible capacity. The electrode materials are able to absorb and give up again the ions from the electrolyte. With the use of optional production modules, operators are able to double the production capacity

5. The product features enough hardness. It's relatively hard, which makes it suitable for higher operating pressures and temperatures. Its operating noise has been reduced as possible

Introduction Auto feeder

Suction feeder, cardboard sheet feeding is smooth and steady. Side board is computer controlled, auto lateral adjustment. The feeder structure is simple and reliable, suitable for large quantity of production orders, easy to maintain. |

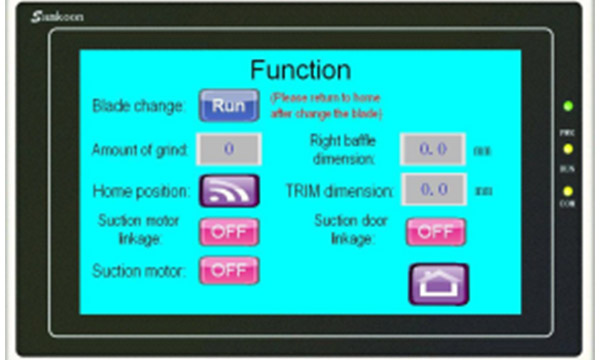

Function

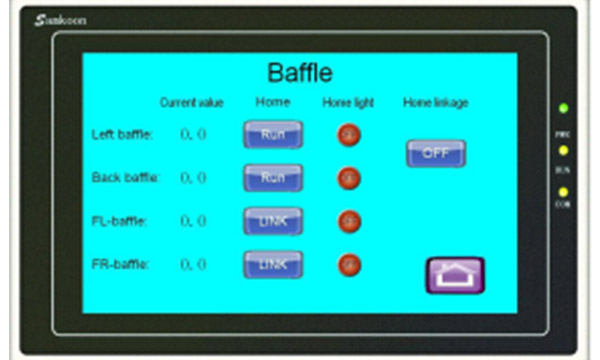

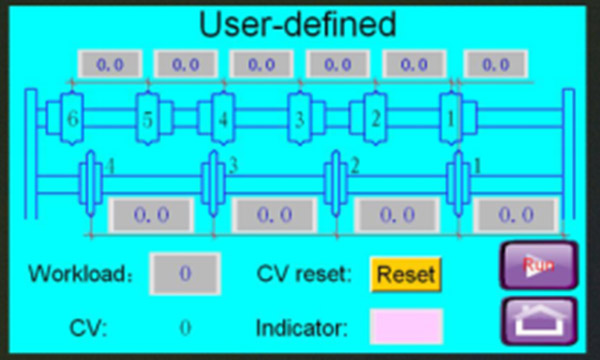

Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

No. | Model | ZBFY-CD2500 | Unit |

1 | Blades & scorer | 4blade 6scorer | / |

2 | Feeder | Auto | / |

3 | Pressure adjustment | Auto | / |

4 | Speed | 160 | m/min |

5 | Max. feeding width | 2500 | mm |

6 | Max. slitting width | 2500 | mm |

7 | Min. slitting width | 200 | mm |

8 | Min. feeding length | 280 | mm |

9 | Min. scoring width | 40x140 | mm |

10 | Feeding thickness | 2-7 | mm |

11 | Air pressure | 0.4 | Mpa |

12 | Main motor power | 5.5 | kw |

13 | Dimension(LxWxH) | 2170x3450x1500 | mm |

14 | Overall net weight | Abt 3800+1500 | kg |

Cardboard ≤ 700gsm

Operation HMI for Auto feeder

Auto Thin Blade Slitter Scorer ZBFY-CD2500

● Auto feeder

● Auto adjusted slitter

● Auto adjusted pre-scorer and scorer

● Auto/manual blade grinder

● Auto adjusted pressure

● Jog function for fine-adjusted

● User-defined function

● Auto counter

● Slitting and scorer Precision ±0.5mm

Operation HMI for Main machine

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

Company Features1. Jingou Packaging Machinery Co., Ltd. has established strategic partnerships with many laser cut paper giants.

2. Our factory invests in high speed and automated equipment to increase efficiency.

3. Our market position is to be the leader in the industry. To achieve this goal, we will grasp new technologies to optimize our products and strengthen our innovative capabilities.