Function

Application: for carton & cardboard manufacturer. Advantages: this machine is PLC+HMI control, can finish pre-pressing, slitting, scoring, trimming in one time pass. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency. Operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. Memory: save 300 orders | Manual feeder Auto adjusted slitter Auto adjusted pre-scorer and scorer Auto/manual blade grinder Auto adjusted pressure Jog function for fine-adjusted User-defined function Auto counter Slitting and scorer Precision ±0.5mm |

SPECIFICATIONS

No. | Model | ZBFY-AD2500 | |

1 | Blade/scorer | 4blade 6scorer | 5blade 8scorer |

2 | Feeder | Manual | |

3 | Pressure adjust | Auto | |

4 | Max. speed | 180m/min | |

5 | Max. feeding width | 2600mm | |

6 | Max. slitting width | 2500mm | |

7 | Min. slitting width | 190mm | |

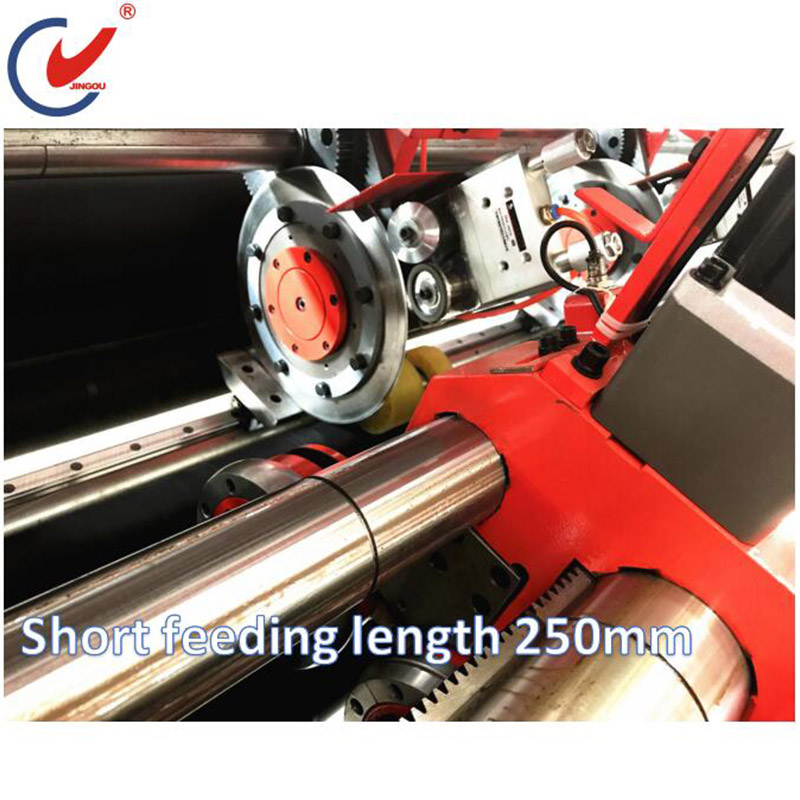

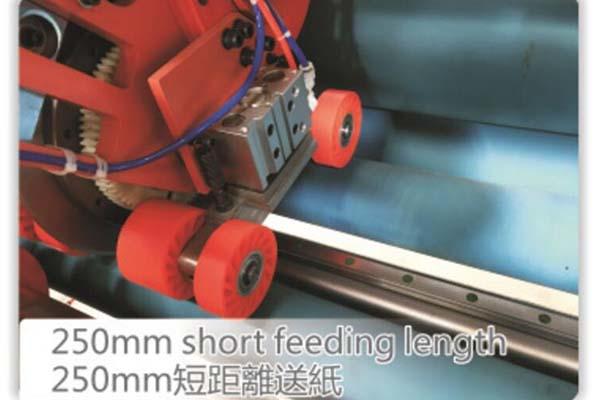

8 | Min. feeding length | 250mm (1for1: 480mm) | |

9 | Min. scoring width | 40x140mm | |

10 | Sheet thickness | 2-7mm | |

11 | Air pressure | 0.4Mpa | |

12 | Main motor power | 4kW | 5.5kW |

13 | Dimension(LxWxH) | 1570x3450x1500mm | |

14 | Overall net weight | 2500kg | 2800kg |

DESCRIBE

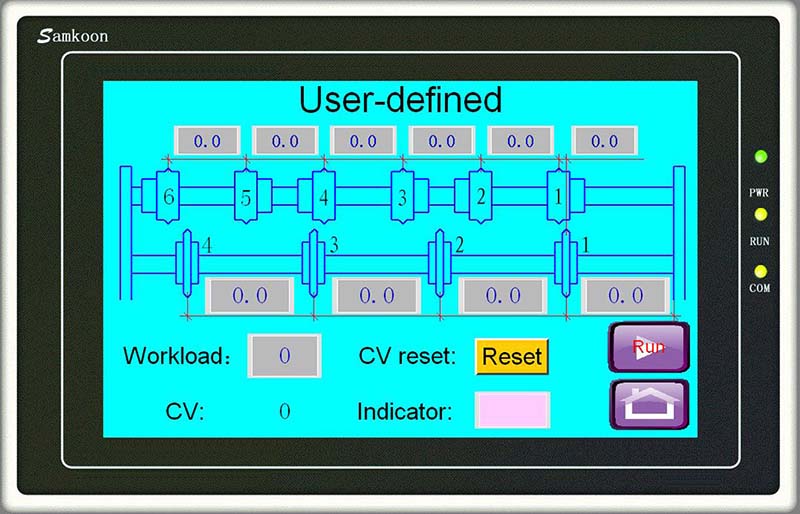

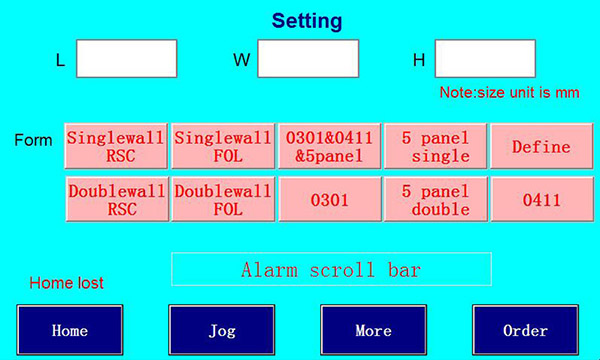

Operation HMI for Main machine

If you have some special work, can use this User-defined function

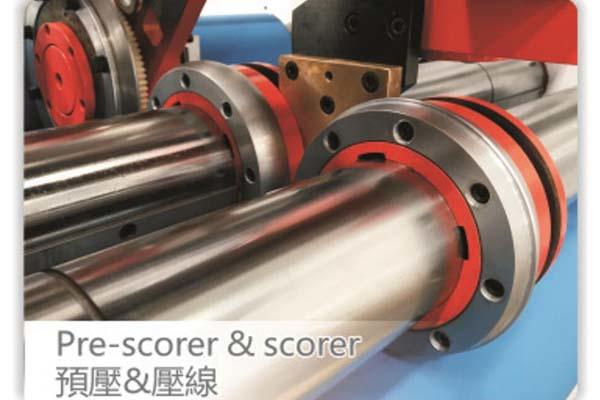

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

After-sales service

● Thanks to developed internet and after-sales network, communication become more and more convenience.

● The reliability of our machines make problem solving much easier, 99% of technical problem can be solved via remote assistance.

● Whenever customer need assistance or ask questions can communicate with the sales staff online, real-time to solve the problem, we are able to provide a full spectrum of services and prompt support.

Model ZH-1000 is the hot sale of the company.The users praise its stability, versatility

and flexibility.It can paste many kinds of boxes. For small ones,it can make 40,000 to 50,000 pcs per hour. It' sideal equipment in printing industry.

| Quality | High quality |

1.Q:What is the machine warranty?

A:one year.

2.Q:Does your machine with CE certificate?

A:Yes, issued by Italian organization

3.Q:What is the production time while placing order?

A:About20 days

4.Q:What is the delivery time?

A:15-30days after get the payment.

5.Q:Can your company handle shipping for customers?

A:Yes, just give us destination sea port or container yard

6.Q:Does the packing strong?

A:Yes, all packages are double-checking before delivery

7.Q:How about after-sales service process?

A: We offer life time A.S.S. Please feel free to contact after-sales department.

8.Q:Are you manufacturer or trading company?

A: we are manufacturer.

9.Q:Do you have machines in stock?

A: for standard model, we have a large quantity in stock. For special model, we need

20-30 days to produce it for you.

10.Q:Do you inspect machines before packing?

A:Of course we do.we have QC department to debug the machine before packing

11.Q:What’s the payment term?

A:T/T 30% in advance, the balance paid before delivery. We also accept payment via

West Union and L/C.

12. Q: Do you accept factory visiting?

A: We are highly greeting for your visiting.

1. Germany Siemens imported double servo drive,precision accuracy,mechanical transmission part is reduced,which can effectively reduce the failure rate of the machinery.

2. Nail box machine the whole control system adopts OMRON PLC control system.

3. The nail box machine control box contactor used in Germany Siemens brand.

4. The relay circuit breaker using French brand Schneider,photoelectric and proximity switch with Japan’s OMRON brand.

5. The bottom die blade adopts Japanese tungsten steel production(wear)

6. The whole set of nail heads are made of Taiwan original parts, and the machine head has longer service life.

7. The transform carton size and adjusting nail carton from just one minute can be completed,greatly saves time and is convenient to operate.

8. The front and rear two-way baffles can be packed without cartons, cartons and boxes.

9. The automatic nail box machine after the paragraph with the function of automatic counting,finished cartons can be set according to the number (2-99)sub stack sent to the conveying machinery terminal, convenient bundling.

10. The machine speed:600 nails per minute.

11. The nail spacing:30-120mm adjustable

12. a dual-purpose can nail a monolithic ground nail carton,twin sheet nail carton,irregular box.

13. The dimensions using all electric control,transform size only 1-2 minutes.

14. It can nail nails/single,double screw///,strengthening nails (two double nail in the middle part of single screw) once completed, can be suitable for different customer requirements of different kinds of nail.

15. The nail spacing:30-120mm adjustable

16. The automatic nail box machine is suitable for small and medium-sized carton factory,rapid and labor-saving binding.

17. The bottom without a cover can also screw.(special instructions)

18. The machine features:corrugated cardboard three,five,seven layer thickness adjustment is full computer control,so it’s rapid and accurate.

19. The machine adopts four servo motor(two head motor and two screw pitch control motor)

20. The machine adjustment(optional)

21. The stacking machine(optional).

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved