Company Advantages1. The material for Jingou Packaging Machinery cardboard scissors is carefully selected. Such properties and behaviors as strength, hardness, durability, flexibility, weight, resistance to heat and corrosion, electrical conductivity, and machinability are required. It can automatically count paper in batches

2. The complete sales network of Jingou Packaging Machinery also helps it to be a leading sheet cutting machine supplier. Thanks to its high-speed motor, this product can quickly achieve a satisfying stacking effect

3. The product features easy maintenance. It is designed with certain automatic function that detects malfunction itself, which greatly reduces the machine checking and maintenance times. Its well-designed casters improve its portability

4. The product is not prone to deform. The tempering process has eliminated the internal stress of work blank to prevent or reduce any deformation. This product can easily achieve high-volume distribution

Introduction Auto feeder

Suction feeder, cardboard sheet feeding is smooth and steady. Side board is computer controlled, auto lateral adjustment. The feeder structure is simple and reliable, suitable for large quantity of production orders, easy to maintain. |

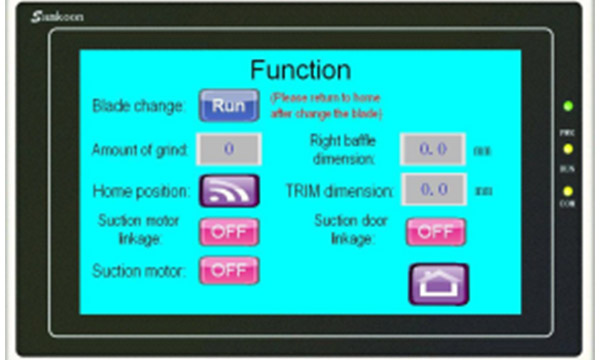

Function

Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

No. | Model | ZBFY-CD2500 | Unit |

1 | Blades & scorer | 4blade 6scorer | / |

2 | Feeder | Auto | / |

3 | Pressure adjustment | Auto | / |

4 | Speed | 160 | m/min |

5 | Max. feeding width | 2500 | mm |

6 | Max. slitting width | 2500 | mm |

7 | Min. slitting width | 200 | mm |

8 | Min. feeding length | 280 | mm |

9 | Min. scoring width | 40x140 | mm |

10 | Feeding thickness | 2-7 | mm |

11 | Air pressure | 0.4 | Mpa |

12 | Main motor power | 5.5 | kw |

13 | Dimension(LxWxH) | 2170x3450x1500 | mm |

14 | Overall net weight | Abt 3800+1500 | kg |

Cardboard ≤ 700gsm

Operation HMI for Auto feeder

Auto Thin Blade Slitter Scorer ZBFY-CD2500

● Auto feeder

● Auto adjusted slitter

● Auto adjusted pre-scorer and scorer

● Auto/manual blade grinder

● Auto adjusted pressure

● Jog function for fine-adjusted

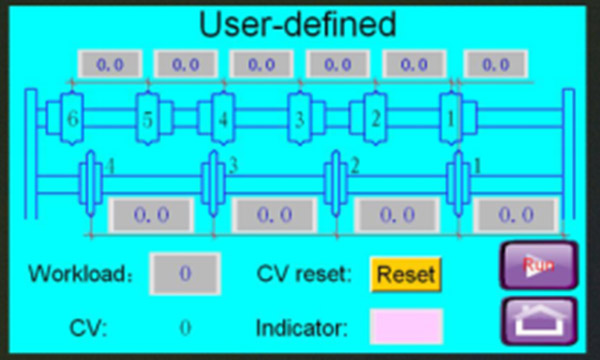

● User-defined function

● Auto counter

● Slitting and scorer Precision ±0.5mm

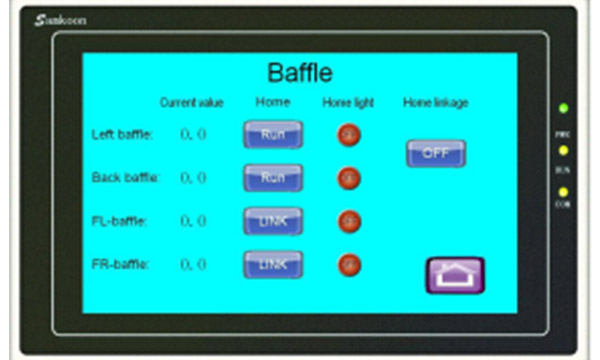

Operation HMI for Main machine

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

Company Features1. With years of involvement in the R&D, design, and production of sheet cutting machine , Jingou Packaging Machinery Co., Ltd. has stood out among many competitors and is widely accepted. All the projects in Jingou Packaging Machinery Co., Ltd. are completed with 100% professionalism.

2. Jingou Packaging Machinery produces card laser cutting machine through contemporary technology.

3. Our professional R&D team is responsible for developing new technologies to optimize products and improve product quality to keep cardboard cutting machine for sale more competitive in this market. The conduct of tenet of laser cut cardboard will give much benefits for the virtuous development of Jingou Packaging Machinery. Get more info!