Company Advantages1. The computerized production method optimizes the overall energy efficiency of Jingou Packaging Machinery cardboard cutting machine to ensure that the environmental impact is minimal. This product gives companies the ability to reliably package and ship right-sized orders

2. The product is significant to lower the running temperature of the device, reducing the hardware loss, therefore extending the service life of the device. This product requires no extra tools or dies

3. The product has a very high elasticity. It will contour to the shape of an object pressing upon it to provide evenly distributed support. All its settings are directly entered from a comfortable touch screen panel

4. This garment has good durability. The adopted fine yarn is tightly bound, which makes the resulting fabric and garment stronger and more durable. Its waste paper suction device helps maintain a clean production environment

Introduction Auto feeder

Suction feeder, cardboard sheet feeding is smooth and steady. Side board is computer controlled, auto lateral adjustment. The feeder structure is simple and reliable, suitable for large quantity of production orders, easy to maintain. |

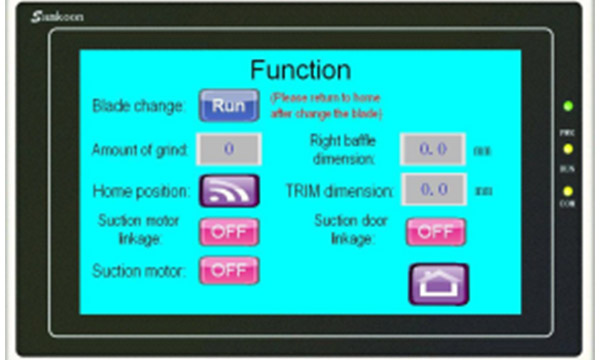

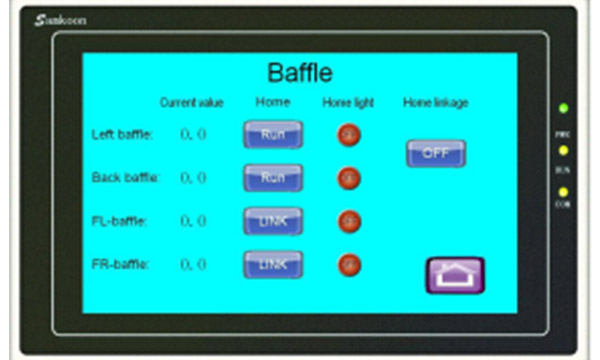

Function

Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

No. | Model | ZBFY-CD2500 | Unit |

1 | Blades & scorer | 4blade 6scorer | / |

2 | Feeder | Auto | / |

3 | Pressure adjustment | Auto | / |

4 | Speed | 160 | m/min |

5 | Max. feeding width | 2500 | mm |

6 | Max. slitting width | 2500 | mm |

7 | Min. slitting width | 200 | mm |

8 | Min. feeding length | 280 | mm |

9 | Min. scoring width | 40x140 | mm |

10 | Feeding thickness | 2-7 | mm |

11 | Air pressure | 0.4 | Mpa |

12 | Main motor power | 5.5 | kw |

13 | Dimension(LxWxH) | 2170x3450x1500 | mm |

14 | Overall net weight | Abt 3800+1500 | kg |

Cardboard ≤ 700gsm

Operation HMI for Auto feeder

Auto Thin Blade Slitter Scorer ZBFY-CD2500

● Auto feeder

● Auto adjusted slitter

● Auto adjusted pre-scorer and scorer

● Auto/manual blade grinder

● Auto adjusted pressure

● Jog function for fine-adjusted

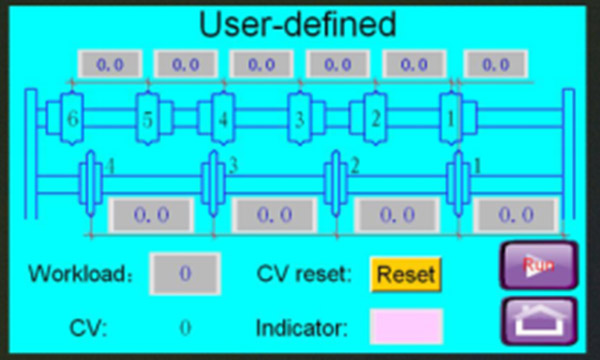

● User-defined function

● Auto counter

● Slitting and scorer Precision ±0.5mm

Operation HMI for Main machine

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

Company Features1. Jingou Packaging Machinery Co., Ltd. has advanced production machines and modern production lines for automatic box making machine. Our sales & marketing team promotes our sales. With their good communication and excellent project coordination skills, they are able to serve our global customers in a satisfactory manner.

2. We have our own manufacturing plant. It is dedicated to R & D experiments, experimental designs, initial process development, and QC activities.

3. We have a modern factory equipped with advanced manufacturing facilities. With the help of these machines, we can achieve a relatively high automation level and increased productivity. Our company bears social responsibilities. Wastewater is treated before it leaves the site, to separate out any oil and other pollutants. Any that are drained straight to rivers or watercourses is subject to intensive purification, and any that goes into the public sewage system meets regulatory standards.