INTRODUCTION

Case King CK25

3 Step quick set-up | ||

1. Choose box type | 2. Input carton information | 3. One button setting |

Introduction The Case King model. CK25 is one of the most advanced box making machine available today. It is designed to solve the problem of small and medium orders of corrugated boxes quickly and easily. All tools are controlled through the simple touch screen. Size change from one style and size of box to another in seconds. Whether you need to produce small gift boxes, large wraps, furniture box, or more complicated boxes, the Case King can make them all at the touch of a button. | ||

Function

Application:for carton manufacturer. Advantages:this machine is PLC+HMI control, can finish auto feed, slot, cross score, angle cut, trim, H-cut, die-cut in one time pass. Special H-slot&score structure, can do small, medium and oversize carton. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency, it is a effective solution for small quantity order. | Easy operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. |

SPECIFICATIONS

No. | Model | CK25 | CaseKing |

1 | Max. Feeding size (WxL) | 2500mm x unlimited | horizontal slotting, max length can be unlimited |

2 | Min. feeding size (WxL) | 120 x 350mm | The min size can go through |

3 | Slotting width | 7mm | Slotting blade width |

4 | Max. slotting depth | 500mm | Slotting blade length |

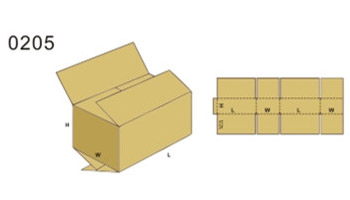

5 | 02xx Max. box height | 1600mm | Max. size between left and right slotting blade |

6 | 02xx Min. box height | 100mm | Min. Size between left and right slotting blade |

7 | Max. angle cutting width | 45mm | Angle blade length |

8 | Feeding thickness | 2-11mm | Gap between feeding rollers |

9 | Speed | 400-600pcs/h | Average speed |

10 | Air pressure | 0.3-0.6Mpa | |

11 | Total motor power | Abt. 15kW | |

12 | Dimension (WxLxH) | 3350x3700x2000mm | main machine size, if 2 unit will be less |

13 | Overall net weight | Abt6000kg | Total weight if 2 unit will be less |

Cardboard ≤ 700gsm

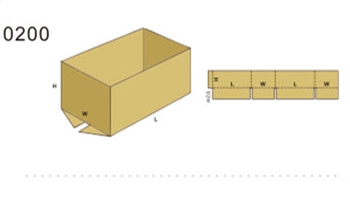

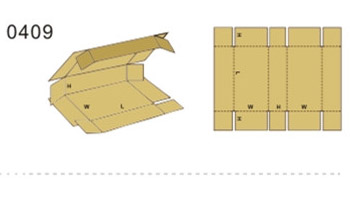

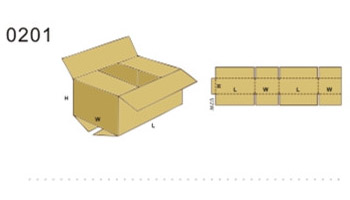

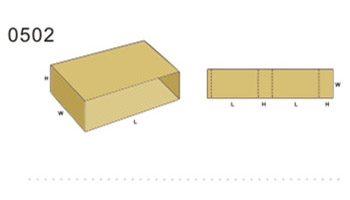

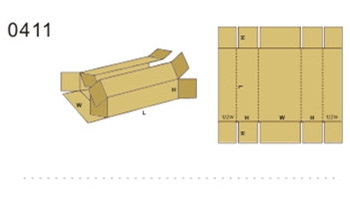

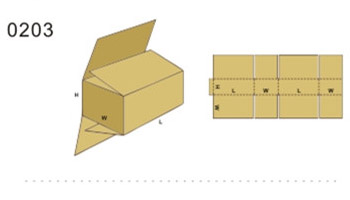

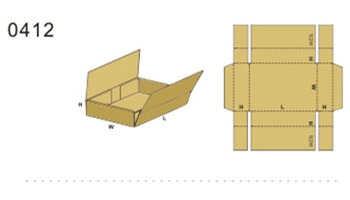

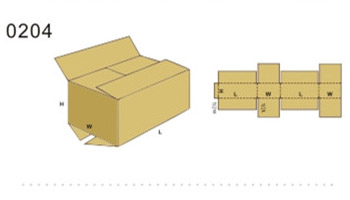

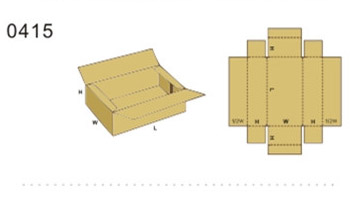

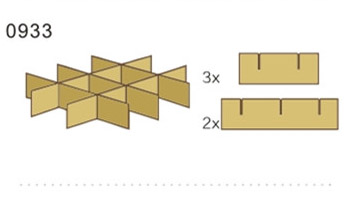

BOXES ACCORDING TO FEFCO (in one pass)

CK25 can also produce box type as follow: (without manual scorer)

● 0301,0452,0453,0911 can use 300

● 0458 can use 0302

● 0900,0902,0903 can use 0901

● 0930,0931,0932,0934,0935 can use 0933

● Define one pass:0228,0230,0231,0454,0455,0904,0905,0906,0907,0908,0909,0910,0913,0914,0920,0940,0942,0945,0946

● Define two pass:0208,0210,0212,0214,0229,0400,0403,0413,0420,0456,0921,0941,0943,0944

● Combination box:0306,0310,0312,0313,0320,0325,0331,0404,0405,0504,0505,0507,0509,0510,0512,0601,0607,0608,0610,0615,0616,0620,0621,0929

YC1650 Corrugated carton box making machine Die Cutting is a special equipment applying to die cutting of advanced colorful boxes and cartons.

1. Gripper bars with high intensity are applicable to all kinds of cardboard, paperboard and corrugated paper.

2. Frontal, back and side registration mechanism ensures great precision of die-cutting.

3.It is easy to eliminate troubles according to the display of trouble shooting.

4.Transducer is adopted to control the main motor in achieving stepless speed variation.

5.The machine has a lot of sensors and safety-ensuring devices to guarantee the safety of operator and the environment.

6.Frontal and back pressure can be adjusted separately.

7.It is convenient to stop the machine by handy. It can also realize die-cutting without clipper margin.

YC1650 Corrugated carton box making machine Die Cutting

Details :

Parameters :

Automatic Flat bed Die cutter |

YC1650 |

Max. Paper Size | 1650*1210mm |

Min. Paper Size | 650*550mm |

Max. die cutting size | 1620*1190mm |

Max running speed | 7500 S/H |

Precision | <=±0.10mm |

Rated Power | 45Kw |

Max working pressure | 400T |

Min. gripper size | 7mm |

Paper available | White board: 120-2000gsm |

Corrugated board: <=8mm | |

Max. feed stack height | 1500mm |

Max. delivery stack height | 1220mm |

Machine weight | 17T |

Overall dimension | 10480*5450*2500mm |

Advantage of our product

1) Safety: CE certified product; outstanding appearance design, photoelectron switches, safety doors, transparent view windows, all devote a perfect and powerful safety to its operators.

2) Stability: Main machine frame walls made of cast iron, worm / worm-gear / jackshaft, all made of special material, make the equipment run and work stably all the time.

3) Low noise: careful manual scraping and grinding, and forced lubricating system both assure this machine of a low noise and steady running.

4) High Precision: Die cutting precision is up to ±0.1%. Paperboard guiding and stopping devices at feeding unit and conveying unit, works with gripper bar guiding and stopping devices and die plate chase locating and locking devices, to devote a perfect die cut product in high precision.

Service

1.One year overall warranty with free supply of spare parts.

2.Supply of spare parts at low (cost) price out of warranty.

3.Free training in our company

4.12 hours on-line service, free support technically

5.Well-adjusted machine before delivery, with operation manuals and disc

6.Overseas services for installation and operation training are available.

7.YONGCHENG ESF service system: butler-like service, professional service, lifetime free service.

Company advantage

1.Technical advantage: a SHANDONG HI-NEW-TECH ENTERPRISE with a powerful R & D technical team, which own 38 patents.

2.Service advantage: a strong and powerful sales and service team. Our products have been to 56 countries, nationwide we have 108 sales, 18 offices, 79 sales agents, available to offer valuable and efficient services before and after sales.

3.Powerful production capacity: designed capacity 500 die cutters annually, meeting fast delivery demands by customers.

4.Quality control advantage: 5S site management mode, there are always a system assurance to all programs from inspection to purchased parts and components, spare part machining, entire machine assembly, ready machine inspection, and so on, every part of workflow

5.Certificate :ISO 9001, CE, BV, SGS

Samples :

(1). Manufacturer or Trading Company

We are a specialized manufacturer for flexo press , flatbed die cut , offset press for 22 years since 1992.

(2). MOQ

1 unit

(3). Shipment

We have cooperated with specialized

(4). Warranty Time

Complete service system, 12 months since arrival of destination port

(5). Payment Terms

T/T, 30% deposit, balance will be paid before shipment; irrevocable L/C at sight

(6) .OEM:

Customized design is available, OEM and ODM are welcomed

(7). After-sale service

Reply your inquires in 24 working hours.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved