Introduction Auto feeder |

Function

Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

SPECIFICATIONS

No. | Model | ZBFY-CD2500 | Unit |

1 | Blades & scorer | 4blade 6scorer | / |

2 | Feeder | Auto | / |

3 | Pressure adjustment | Auto | / |

4 | Speed | 160 | m/min |

5 | Max. feeding width | 2500 | mm |

6 | Max. slitting width | 2500 | mm |

7 | Min. slitting width | 200 | mm |

8 | Min. feeding length | 280 | mm |

9 | Min. scoring width | 40x140 | mm |

10 | Feeding thickness | 2-7 | mm |

11 | Air pressure | 0.4 | Mpa |

12 | Main motor power | 5.5 | kw |

13 | Dimension(LxWxH) | 2170x3450x1500 | mm |

14 | Overall net weight | Abt 3800+1500 | kg |

Cardboard ≤ 700gsm

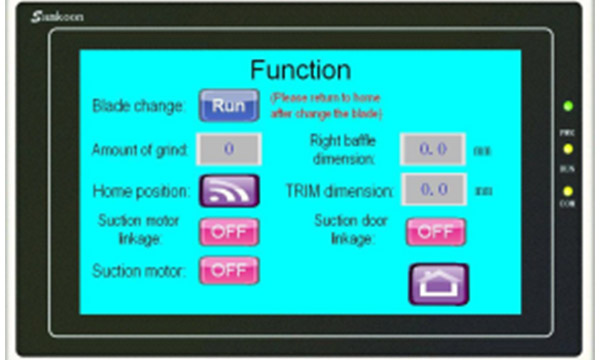

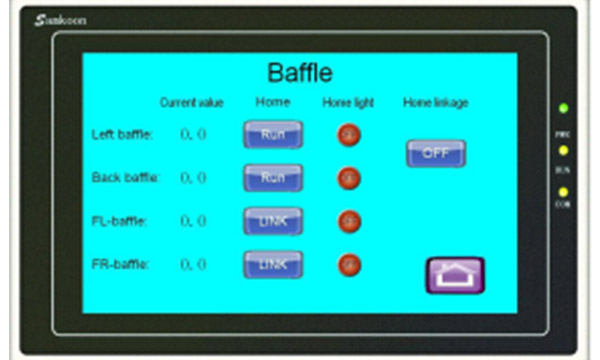

Operation HMI for Auto feeder

Auto Thin Blade Slitter Scorer ZBFY-CD2500

● Auto feeder

● Auto adjusted slitter

● Auto adjusted pre-scorer and scorer

● Auto/manual blade grinder

● Auto adjusted pressure

● Jog function for fine-adjusted

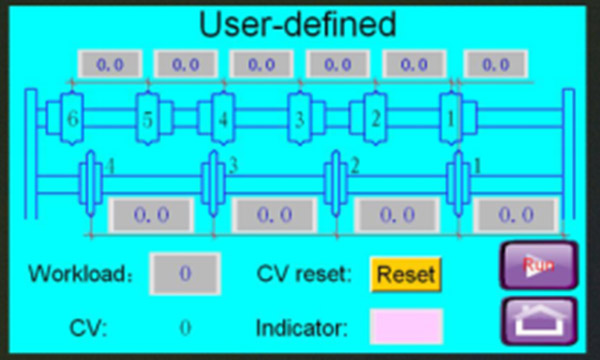

● User-defined function

● Auto counter

● Slitting and scorer Precision ±0.5mm

DETAILS

Operation HMI for Main machine

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

1.Parameters:

Model: | TDA-430 |

Max size: | 420*410*120 |

The minimum processing size: | 70*52*10mm |

Total Power: | T2.2kw/220v |

Speed: | 15--25pcs/min |

Dimensions: | 1200*900*2050mm |

Total Weight: | 1100kg |

2.Pictures:

3.Description:

Product features;

ZX--450B automatic earth cover molding machine are developed by our company,production, stable performance,wide range of uses.

The machine is processing Hardcover Gift boxes,boxes ideal world of automation equipment,the pipeline will be good through artificial boxes and tissue paper orientaion,and then locate good Cassette into the machine mold,the machine automatically run,edging,folding,pressing bubble once completed.Produce hardcover boxes per minute 15-20,greatly improving production efficiency,reduce production coste.

Performance;

1,The machine is completed by a servo motor,PLC programmable control.

2,The machine commissioning completed by the HMI selective, simple and easy to adjust.

3,The machine contfol accessories for all full use of intemational high-end brands,the failure of low and high accuracy.

4,The machine with a fault alarm functions,such as and part of the failure,the alarm will whistle,fault will be displayed on the screen.

5,The machine can touch with emergency stop switch,if an emergency press stops automatically.

4.Company strength:

1.15 years factory experience

2.10 years export experience

3.Over one hundred professional factory workers

4.100% quality guarantee,supply all kinds of certificates

5.Good after-sales serive,we send engineers to repair machine overseas.

6.Primary products:

Automatic High Speed Flute Laminater

ZXSCM Book Case Making Machine

650UV Coating Machine

ZX-650C Manual Paper Pasting Machine

Box Making Machine

Hot Melt Gluing Machine and Gluing Machine

Table Gluing Machine

Paper Pressing Machine.etc

7.Following is our factory pictures:

5.Certificate:

6.Trade show:

7.Packaging & Loading:

Welcome to visit our factory!

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved