INTRODUCTION

Case King CK25

3 Step quick set-up | ||

1. Choose box type | 2. Input carton information | 3. One button setting |

Introduction The Case King model. CK25 is one of the most advanced box making machine available today. It is designed to solve the problem of small and medium orders of corrugated boxes quickly and easily. All tools are controlled through the simple touch screen. Size change from one style and size of box to another in seconds. Whether you need to produce small gift boxes, large wraps, furniture box, or more complicated boxes, the Case King can make them all at the touch of a button. | ||

Function

Application:for carton manufacturer. Advantages:this machine is PLC+HMI control, can finish auto feed, slot, cross score, angle cut, trim, H-cut, die-cut in one time pass. Special H-slot&score structure, can do small, medium and oversize carton. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency, it is a effective solution for small quantity order. | Easy operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. |

SPECIFICATIONS

No. | Model | CK25 | CaseKing |

1 | Max. Feeding size (WxL) | 2500mm x unlimited | horizontal slotting, max length can be unlimited |

2 | Min. feeding size (WxL) | 120 x 350mm | The min size can go through |

3 | Slotting width | 7mm | Slotting blade width |

4 | Max. slotting depth | 500mm | Slotting blade length |

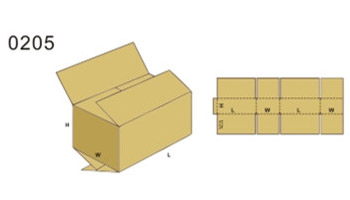

5 | 02xx Max. box height | 1600mm | Max. size between left and right slotting blade |

6 | 02xx Min. box height | 100mm | Min. Size between left and right slotting blade |

7 | Max. angle cutting width | 45mm | Angle blade length |

8 | Feeding thickness | 2-11mm | Gap between feeding rollers |

9 | Speed | 400-600pcs/h | Average speed |

10 | Air pressure | 0.3-0.6Mpa | |

11 | Total motor power | Abt. 15kW | |

12 | Dimension (WxLxH) | 3350x3700x2000mm | main machine size, if 2 unit will be less |

13 | Overall net weight | Abt6000kg | Total weight if 2 unit will be less |

Cardboard ≤ 700gsm

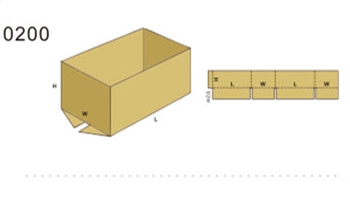

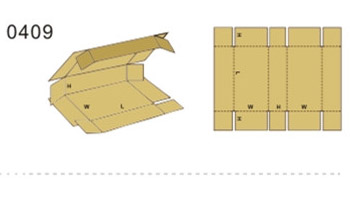

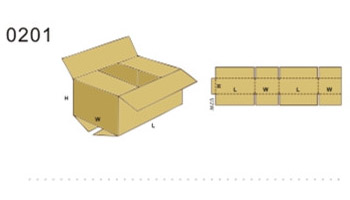

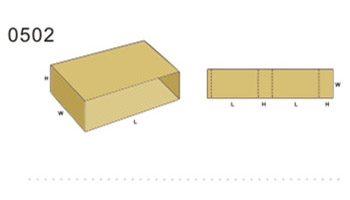

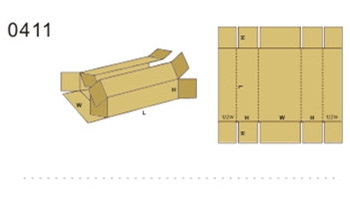

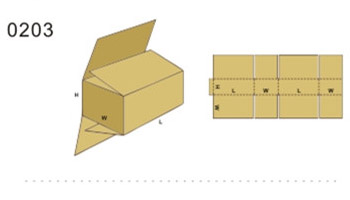

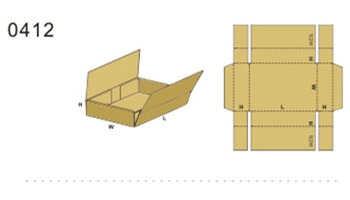

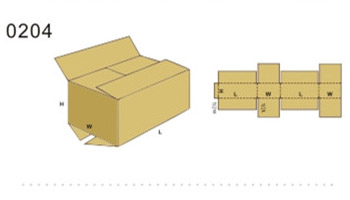

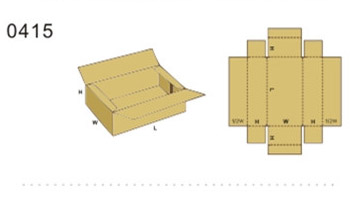

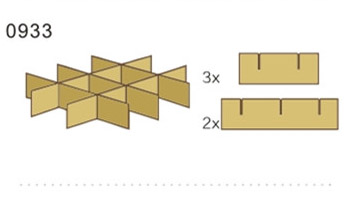

BOXES ACCORDING TO FEFCO (in one pass)

CK25 can also produce box type as follow: (without manual scorer)

● 0301,0452,0453,0911 can use 300

● 0458 can use 0302

● 0900,0902,0903 can use 0901

● 0930,0931,0932,0934,0935 can use 0933

● Define one pass:0228,0230,0231,0454,0455,0904,0905,0906,0907,0908,0909,0910,0913,0914,0920,0940,0942,0945,0946

● Define two pass:0208,0210,0212,0214,0229,0400,0403,0413,0420,0456,0921,0941,0943,0944

● Combination box:0306,0310,0312,0313,0320,0325,0331,0404,0405,0504,0505,0507,0509,0510,0512,0601,0607,0608,0610,0615,0616,0620,0621,0929

Main technical data

1. Model: WJ150-1600 5ply corrugated carton production line

2. Max work Speed: 150 m/min.

Normal work speed: 120-130m/min

3. Manufacture Width: 1600 mm

b. Surface roll width: 1650mm

4. a. Flute Type: UV type.

b. Flute height:A flute 4.3mm, B flute 2.65mm, C flute 3.65mm, E flute: 1.8mm

5. Steam Pressure: Max 1.6Mpa, normal about 1.2-1.3MPa

6. Steam Consumption: 2900 -3200kg/h (suggest use 4T boiler)

7. Voltage: 380V, 50Hz.

8. (Corrugated paperboard: 150-180g/m2, Corrugated paper: 150--180g/m2, liner paper: 150-180g/m2)

Notes: Quality accords with national B grade above standard, Paper water containing rate: 11%±1.

9. Total installed power: 300KW, normal work use: about 240kw

10. Area that machine requires: 72m×10m x 3.8m(length x width x height)

RS-1500HA Hydraulic Mill Roll Stand

Specification:

1. Working width: Max: 1600mm, Min: 900mm

2. Paper roll diameter: Max1500mm, Min350mm

3. Max loading capacity at each side: 3200kg

4. Max working pneumatic pressure: 0.6-0.9Mpa

5. Main shaft diameter: 215mm

6. Power requirements: 440V, 50Hz

Machine Introduction:

1. Symmetric structure with two paper reels loading capacity, allowing paper roll change without downtime

2. The lift-down arm adopted with cast iron curve structure, slinky, firm and steady.

3. Lift-down, clamp-loosen and left-right move are controlled by hydraulic pressure.

4. Adopts expansion chuck

5. Paper tension controlled by pneumatically operated disc brake, manual setting the tension easily, the tension control unit in auto splicer will take over the control of the brake torque.

Raw materials & purchased components:

a. Main shaft: High quality seamless steal pipe

b. Both sides wallboard: resin sand.

d. Bearing: Chinese famous brand

e. Electric components: Schneider or Omron import product.

f. Pneumatic components: Airtac, Taiwan.

g. Hydraulic components: Beijing Huade Hydraulic Industrial Group Co., Ltd

SF-320S Single Facer

Specification:

Working width: Max: 1600mm

Design speed: 160m/min, normal work speed: 120-150m/min

Working gas pressure: 0.6--0.9Mpa, steam pressure: 0.9--1.3Mpa

Steam consumption: 0.5--0.8t/h, temperature requirements: 160—200 centigrade

Power requirements: 440V, 50Hz

Corrugating roller width:1650mm

Machine Introduction:

1. Vacuum suction Fingerless design provides perfect flute formation in high speed manufacturing.

2. Individual immersion oil gear type drive box, separating dynamic vibrations improve running stability, easy and fast for maintenance. Three shafts drive lower corrugating roller, pressure roller and gluing roller.

3. The exhaust fun motor drive suction case, absorb corrugated paper surround the corrugating rollers about 180 degree where is positive-pressure zone, make sure big strength for flute making.

4. Lower corrugating roller suction channel within 2mm, prevent the 2layer carton sheet with stripe on the surface of the face paper.

5. With “Self-circulating glue feeding system”, save glue and improve work efficiency.

6. Pneumatic control for pressure roller load/unload, with cushioning effect.

8. Motorized guide plate adjusted the pasting width.

9. Automatic added lubricates oil device.

10. The steel blank on top of machine can separate disconnect to clean garbage inside, not need disconnect whole machine.

11. Include motorized glue quantity adjustment with digital readout system.

12. Glue unit is engaged and disengaged by cylinder movement, generous opening ensure convenient cleaning and maintenance.

13. Adjust glue thickness: Quantity of pasting glue and controlling glue is controlled by the clearance between glue roller and doctor roller adjust by manual worm box.

Raw materials & purchased components:

a. Corrugating roller: made in Beijing Package Group.

Corrugating rollers made of 48CrMo alloy steel, and induction hardened with hardness up to HRC58-60.

Flute: A flute 4.7mm, C flute: 3.5mm, B flute, 2.65mm, E flute 1.27mm, and flute profile UV unless marked. Special fluting requirements can be customized.

Upper/Lower Corrugating roller diameter: 318mm/320mm. made of 48CrMo alloy steel, and induction hardened with hardness up to HRC58—60.

b. Pressure roller diameter: 340mm. Adopts 45# seamless steel pipe, surface with hardening treatment.

c. Gluing roller diameter: 240mm, Adopts 45# seamless steel pipe, surface with special experienced beautifying and chrome plating treatment.

d. Doctor roller diameter: 120mm, Adopts 20# seamless steel pipe, surface with Modulation and electroplating treatment.

e. Pre-heat roller diameter: 400mm, Adopts 20G steel, thickness of wallboard 20mm, with chromed treatment.

f. Wallboard and seat: resin sand

g. Driving part seat: channel steel welding form.

h. Rotary joint, metal tube: made in Wanxiang group, China largest company

I. Bearing and bearing with seat: main bear made in NSK, Japan, others made in China famous brand.

k. Adjusting glue width motor: made in CPG Taiwan

l. Electric components: Schneider or Omron import product.

m. Pneumatic components: Airtac, Taiwan and China

n. Frequency converters: made in Delta Taiwan.

BS-T Bridge Conveyer

Description:

This is conveyer bridge is designed for transport single-side corrugated paper by the top of the single facer to the multiplex pre-heater.

Specification:

Working width: Max: 1600mm,

Design speed: 150m/min, normal work speed: 120-150m/min

Machine Introduction:

1. Adopts suction tension device, use high pressure adsorption motor to suction the single face paper, make it flat to input the next process.

2. Installing two operate board, could be adjust on the bridge and ground.

3. Paper receiving device adopts independent frequency conversion control, manufacture enough single face paper to wave type, and make sure enough storage of single face paper, to keep in-phase different speed in manufacture.

4. With feeding paper frame on the bridge and two conveyer belt to transport the single face paper to the bridge, forming wave type to storage the single face paper.

5. The Automatic adjust the position of single face paper, reduce waste paper ratio of the manual operation.

6. Equipped block part, in order to single face paper stack well on the bridge when the machine in high speed.

7. With safety rails, stair cases and board to insure safety of the operator also make easy to operate.

Raw materials & purchased components:

1. Main shaft channel steel: 20# steel

2. Receiving paper part belt: Nylon industrial belt

3. Storage part belt: Parallel conveyor belt.

4. Electric components: Schneider or Omron import product.

GL-288D Gluing Machine

Specification:

Manufacture width: 1800mm

Max design speed: 180mm/min

Economic work speed: 120-150mm/min

Temperature requirements: 150~200°C

Steam pressure: 1.12--1.3MPa

Steam consumption: 0.1~0.15MPa

Compress air: 0.6--0.9MPa

Power requirements: 440V, 50Hz

Pressing method: pressing roller type, pressing board type optional

Each roller diameter, thickness and manufacture

Pre-heating roller diameter: 325mm, thickness 20mm, accurate grinding and chromed

Guiding paper roller diameter: 120mm, thickness 15mm, accurate grinding and chromed

Gluing roller diameter: 288mm, thickness 30mm, accurate grinding and chromed

Doctor roller diameter: 100mm, thickness 15mm, accurate grinding and chromed

Machine Introduction:

1. Independent motor driving, frequency conversion controlled.

2. Gluing roller surface experienced beautifying and chromed.

3. Pressing roller adopts high quality steel product, accurate grinding and chromed.

4. Pressing roller type with high manufacture efficiency, pneumatic control, easy and fast to operate.

5. Automatic recycle pasting glue device control the quantity of glue, avoid glue precipitate, and in order to the quality of glue and save glue.

6. Add heating device, make the glue pasting fast.

Raw materials & purchased components:

a. Wallboard: steel board

b. Bearing: China famous brand

c. Electric components: Schneider or Omron import product.

d. Air pneumatic components: Airtac, Taiwan.

DF-768 Double Facer

Glue Making System

Electric System

Pneumatic System

SP-S Steam System

Thin blade slitter scorer-lifting type----SJBDY1600

NC-180N Helical Knife Cutoff

CF-150T Sheet Delivery

If you want to get further information, please contact me.

Automatic Carton Sealer

Imperial Associates is specializes in providing fully integrated automatic packaging machinery to design and implementation of automatic cartooning packaging systems. Through years of experience and continually catering to special applications for clients, we can provide custom build solutions for complete cartooning solution for customer's various packaging requirements.

Automatic carton sealer adopts three motor driving, top and bottom sealing suit for little heavy cartons. Automatically adjust the height and the width for different size of cartons, suit for pack different cartons at the same time. Advanced pneumatic control system compare with the complicated electrical control system, and the length of carton not limited. This case sealer can be stand-alone operations also can be used with fully automatic packaging lines.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved