Company Advantages1. The process review of Jingou Packaging Machinery industrial cardboard cutter covers every step of the purchasing, manufacturing and shipping process to ensure the quality of the product can meet the highest standard in the rubber and plastic industry. This product performs well in memorizing multiple orders at the same time

2. This product can turn out thousands of identical outcomes. Production has thus been standardized. Only this kind of product is capable of mass production. It has a simple structure that allows operators to work more relaxingly

3. This product has the required safety. Different requirements regarding architecture and risk classification of this product have been considered carefully in the manufacture. Equipped with an automatic board feeder, this product features high efficiency

4. It is renowned for security. It is built with safety mechanisms, including overpressure protection, which aims to prevent any accidents. Built-in waste separation function, this product meets the needs of sustainability practices

5. This product is corrosion resistant. It has been tested in salt fog harsh environment to determine its resistance to the effects of a salt atmosphere. This product has been exported to Southeast Asia, Europe, South America, the Middle East, Africa, etc

Introduction Auto feeder

Suction feeder, cardboard sheet feeding is smooth and steady. Side board is computer controlled, auto lateral adjustment. The feeder structure is simple and reliable, suitable for large quantity of production orders, easy to maintain. |

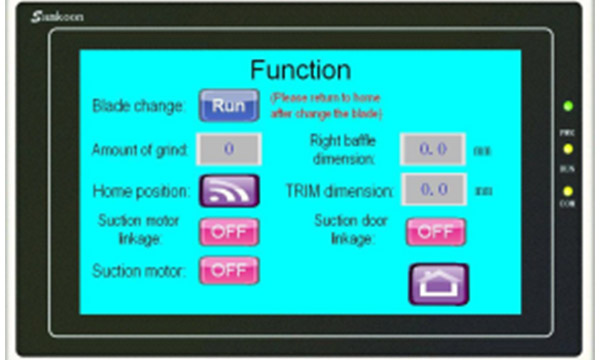

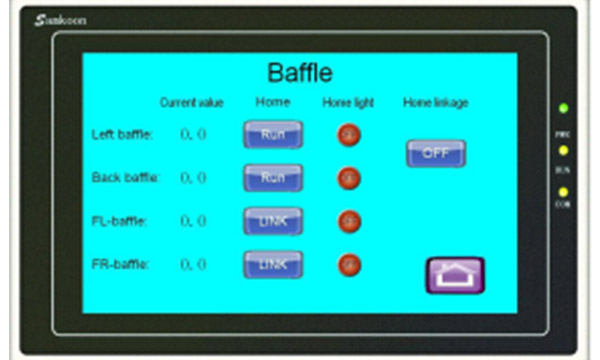

Function

Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

No. | Model | ZBFY-CD2500 | Unit |

1 | Blades & scorer | 4blade 6scorer | / |

2 | Feeder | Auto | / |

3 | Pressure adjustment | Auto | / |

4 | Speed | 160 | m/min |

5 | Max. feeding width | 2500 | mm |

6 | Max. slitting width | 2500 | mm |

7 | Min. slitting width | 200 | mm |

8 | Min. feeding length | 280 | mm |

9 | Min. scoring width | 40x140 | mm |

10 | Feeding thickness | 2-7 | mm |

11 | Air pressure | 0.4 | Mpa |

12 | Main motor power | 5.5 | kw |

13 | Dimension(LxWxH) | 2170x3450x1500 | mm |

14 | Overall net weight | Abt 3800+1500 | kg |

Cardboard ≤ 700gsm

Operation HMI for Auto feeder

Auto Thin Blade Slitter Scorer ZBFY-CD2500

● Auto feeder

● Auto adjusted slitter

● Auto adjusted pre-scorer and scorer

● Auto/manual blade grinder

● Auto adjusted pressure

● Jog function for fine-adjusted

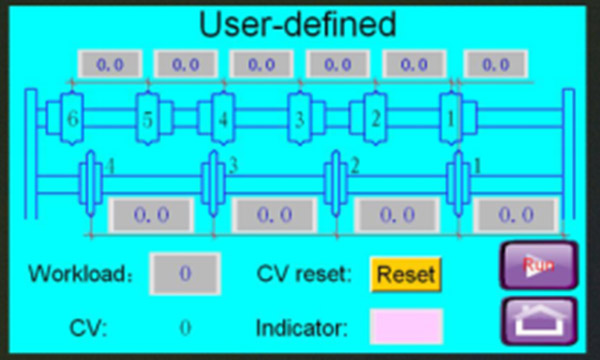

● User-defined function

● Auto counter

● Slitting and scorer Precision ±0.5mm

Operation HMI for Main machine

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

Company Features1. As a professional developer and manufacturer, Jingou Packaging Machinery Co., Ltd. possesses abundant knowledge and experience in producing industrial cardboard cutter . Jingou Packaging Machinery Co., Ltd. has a considerable manufacturing capacity with dozens of sets of cardboard cutting machine processing equipment.

2. box making machine is very easy to be installed for its slitting line .

3. Jingou Packaging Machinery Co., Ltd.'s strong manufacturing capabilities effectively fuel innovation in core cutting machine design. We are mindful of our impact on the environment. We are committed to reducing carbon emissions, lowering our water use, and minimizing our waste.