INTRODUCTION

Case King CK25

3 Step quick set-up | ||

1. Choose box type | 2. Input carton information | 3. One button setting |

Introduction The Case King model. CK25 is one of the most advanced box making machine available today. It is designed to solve the problem of small and medium orders of corrugated boxes quickly and easily. All tools are controlled through the simple touch screen. Size change from one style and size of box to another in seconds. Whether you need to produce small gift boxes, large wraps, furniture box, or more complicated boxes, the Case King can make them all at the touch of a button. | ||

Function

Application:for carton manufacturer. Advantages:this machine is PLC+HMI control, can finish auto feed, slot, cross score, angle cut, trim, H-cut, die-cut in one time pass. Special H-slot&score structure, can do small, medium and oversize carton. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency, it is a effective solution for small quantity order. | Easy operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. |

SPECIFICATIONS

No. | Model | CK25 | CaseKing |

1 | Max. Feeding size (WxL) | 2500mm x unlimited | horizontal slotting, max length can be unlimited |

2 | Min. feeding size (WxL) | 120 x 350mm | The min size can go through |

3 | Slotting width | 7mm | Slotting blade width |

4 | Max. slotting depth | 500mm | Slotting blade length |

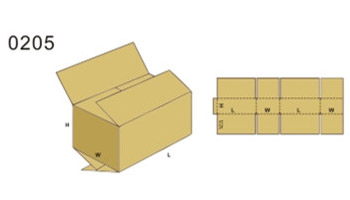

5 | 02xx Max. box height | 1600mm | Max. size between left and right slotting blade |

6 | 02xx Min. box height | 100mm | Min. Size between left and right slotting blade |

7 | Max. angle cutting width | 45mm | Angle blade length |

8 | Feeding thickness | 2-11mm | Gap between feeding rollers |

9 | Speed | 400-600pcs/h | Average speed |

10 | Air pressure | 0.3-0.6Mpa | |

11 | Total motor power | Abt. 15kW | |

12 | Dimension (WxLxH) | 3350x3700x2000mm | main machine size, if 2 unit will be less |

13 | Overall net weight | Abt6000kg | Total weight if 2 unit will be less |

Cardboard ≤ 700gsm

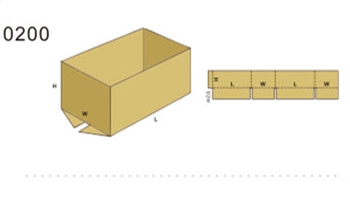

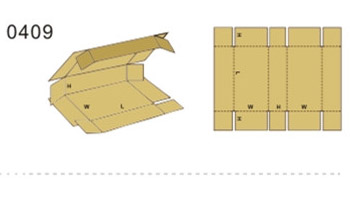

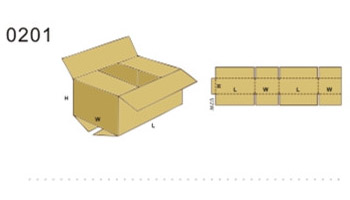

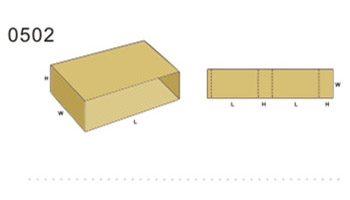

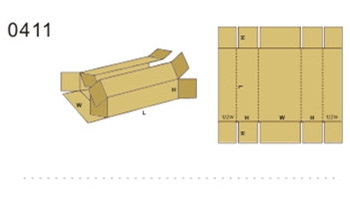

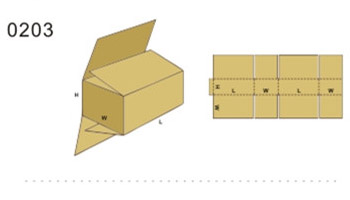

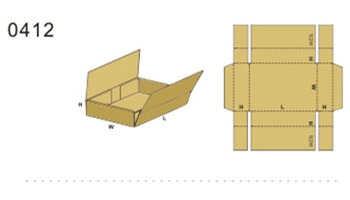

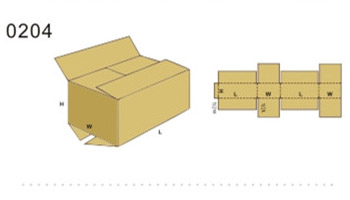

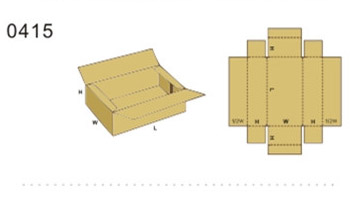

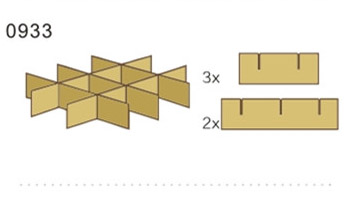

BOXES ACCORDING TO FEFCO (in one pass)

CK25 can also produce box type as follow: (without manual scorer)

● 0301,0452,0453,0911 can use 300

● 0458 can use 0302

● 0900,0902,0903 can use 0901

● 0930,0931,0932,0934,0935 can use 0933

● Define one pass:0228,0230,0231,0454,0455,0904,0905,0906,0907,0908,0909,0910,0913,0914,0920,0940,0942,0945,0946

● Define two pass:0208,0210,0212,0214,0229,0400,0403,0413,0420,0456,0921,0941,0943,0944

● Combination box:0306,0310,0312,0313,0320,0325,0331,0404,0405,0504,0505,0507,0509,0510,0512,0601,0607,0608,0610,0615,0616,0620,0621,0929

Product Description

1,Automatical Leader.printer,slotter in One times.

2,Maintenance and ease of use.

3,Flexo printing

4,passed CE and ISO

| No Additional Cost corrugated paper packing box printing machine |

Introduction of No Additional Cost corrugated paper packing box printing machine

The phase and box height are controlled by computerized system(CNC) with the characteristics like order storage ,quick order changing and convenient control.

1.Whole adsorption feeding printing slotting and die-cutting machine adopts suction lead edge feeding with Double plastic core-rubber-tires at the front and at the end of the machine guarantee the precision of the equipment.

2.Doctor blade system is optional. Rubber roll: best inking. Dual docor blades system: perfect spot print.

3.Optional single and double slotting units can meet different needs of selection.

4.Precision linear guide horizontal displacement systems is equipped with slotting unit.

5.Speed difference compensation system is equipped with Die unit, automatic longitudinal and lateral displacement is equipped with rubber cushion roller .

6.Transmission gears use 40 chrome steel after high-frequency quenching and gear grinding in accordance with national level 6 standard.

7.Electrical components, transmission bearings, pneumatic control components etc. Are all in accordance with the national standard.

Stacking department

1, catch paper arm can be manual or automatic operation, has insurance mechanism, prevent catch paper arm suddenly whereabouts, ensure the safety of operating personnel.

2, bed table lifting and down force, the chain drive.

3, stack height is 1600 mm.

4, bed table with cardboard stacking automatically adjust tilt height, lifting motor, with brake function. Bed table can maintain a fixed position, not falling.

5, vapour-pressure type Lift the paper mechanism ,when cardboard stack to a predetermined height, catch paper pallet automatically open, the support hold up the cardboard.

6, Planar wrinkles belt , prevent the cardboard down glide .

Gluer machine & stitcher machine

1.Many years expertise and professional experience in designing and manufacturing.

2.Design and customize according to customers'requirements.

3.High levels of performance,quality and reliability of all equipments and services.

4.Reliable quality proven by customers both at home and abroad.

5.Reasonable prices without compromising any products efficiency.

6.Promptness in both equipment delivery and technical support pre-and after sales.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved