INTRODUCTION

Case King CK25

3 Step quick set-up | ||

1. Choose box type | 2. Input carton information | 3. One button setting |

Introduction The Case King model. CK25 is one of the most advanced box making machine available today. It is designed to solve the problem of small and medium orders of corrugated boxes quickly and easily. All tools are controlled through the simple touch screen. Size change from one style and size of box to another in seconds. Whether you need to produce small gift boxes, large wraps, furniture box, or more complicated boxes, the Case King can make them all at the touch of a button. | ||

Function

Application:for carton manufacturer. Advantages:this machine is PLC+HMI control, can finish auto feed, slot, cross score, angle cut, trim, H-cut, die-cut in one time pass. Special H-slot&score structure, can do small, medium and oversize carton. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency, it is a effective solution for small quantity order. | Easy operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. |

SPECIFICATIONS

No. | Model | CK25 | CaseKing |

1 | Max. Feeding size (WxL) | 2500mm x unlimited | horizontal slotting, max length can be unlimited |

2 | Min. feeding size (WxL) | 120 x 350mm | The min size can go through |

3 | Slotting width | 7mm | Slotting blade width |

4 | Max. slotting depth | 500mm | Slotting blade length |

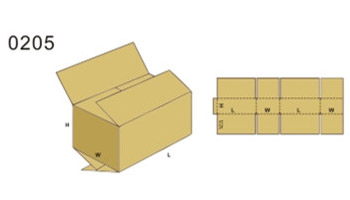

5 | 02xx Max. box height | 1600mm | Max. size between left and right slotting blade |

6 | 02xx Min. box height | 100mm | Min. Size between left and right slotting blade |

7 | Max. angle cutting width | 45mm | Angle blade length |

8 | Feeding thickness | 2-11mm | Gap between feeding rollers |

9 | Speed | 400-600pcs/h | Average speed |

10 | Air pressure | 0.3-0.6Mpa | |

11 | Total motor power | Abt. 15kW | |

12 | Dimension (WxLxH) | 3350x3700x2000mm | main machine size, if 2 unit will be less |

13 | Overall net weight | Abt6000kg | Total weight if 2 unit will be less |

Cardboard ≤ 700gsm

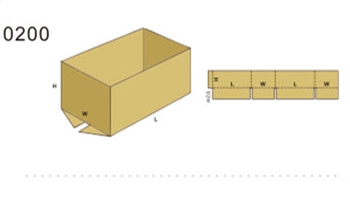

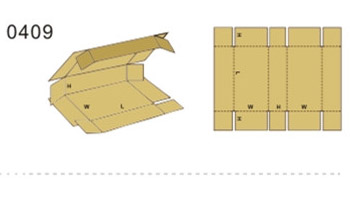

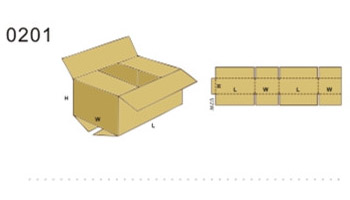

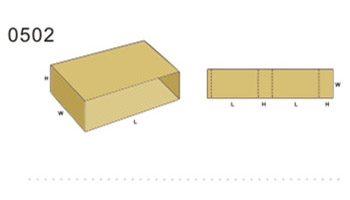

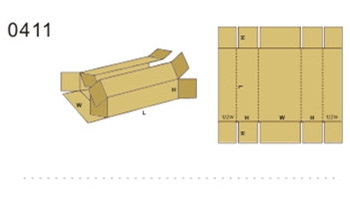

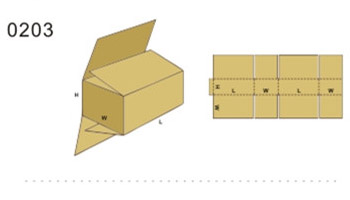

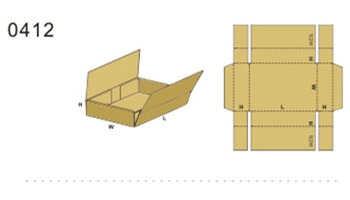

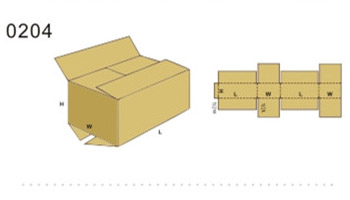

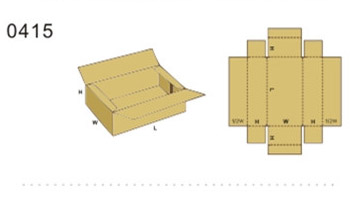

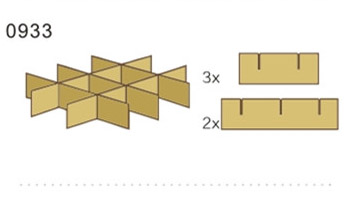

BOXES ACCORDING TO FEFCO (in one pass)

CK25 can also produce box type as follow: (without manual scorer)

● 0301,0452,0453,0911 can use 300

● 0458 can use 0302

● 0900,0902,0903 can use 0901

● 0930,0931,0932,0934,0935 can use 0933

● Define one pass:0228,0230,0231,0454,0455,0904,0905,0906,0907,0908,0909,0910,0913,0914,0920,0940,0942,0945,0946

● Define two pass:0208,0210,0212,0214,0229,0400,0403,0413,0420,0456,0921,0941,0943,0944

● Combination box:0306,0310,0312,0313,0320,0325,0331,0404,0405,0504,0505,0507,0509,0510,0512,0601,0607,0608,0610,0615,0616,0620,0621,0929

Pre-sales

ZhenHua Machine People understand how to choose the appropriate and cost-effective machine, and what is important for our customers.

Please tell us what you need, we will identify the most suitable solution for you.

OEM service is accepted. All machine are available on request, with or without logo.If you need OEM service with your own logo or products, please let us know.

If you have any other specific requirements, please do not hesitate to contact us.

On sale

As all your requestment, we will supply best suggestion and solution on time.

Any time, you have any enquery, please feel free to contact us.

You could contact us by e-mail, Skype, Whatsapp, Wechat and QQ.

Welcome you to visit our factory to check our quality.

We will pick you up from airport or train station.

QC

All Zhenhua machine will be tested by our QC department before shipping, to ensure each machine will work well after they reach you. The QC is through all production, from raw materials, processing, assembling, finished machine testing.

Assemble/Installation and Test

We can send our engineer to your site for installing and testing the machine, but you must be responsible for the visa fees and round trip flight tickets and the accommodation and food of the engineer,and should pay wage to engineer.

After-sale service

Problems, assembly or operation?

Please inform us. we will send you the relevant user manuals or instructions immediately.

We have video guidance or instructions as well. If all these are not working, please feel free to contact us directly.

Warranty

The machine guarantee is 1 year and within 12 months, if any spare parts damaged , we will offer the spare parts freely. But the buyer shall afford the courier charge.

The electrical components, the loss by nature and artificial damage created by unprofessional operation (broken by person), not in maintenance scope.

Use and Characteristics for Semi Automatic 2 Color Carton Box Making Machine Prices:

The machine can be composed of two-color, three color, four-color printing slotting die cutting machine, while providing a complete printing, slitting, creasing, die cutting, corner cutting process, and the advantages of similar products in the absorption of the aircraft based on the all- new design, has a beautiful appearance, novel, compact, high-resolution printing, color printing error is small, easy adjustment and accurate, can achieve seamless transmission gear, and can achieve non-stop printing roller electric phase adjustment of 360 degrees, the aircraft manual and pneumatic lift version has two structural forms, pneumatic structure air can be achieved with ink and inking roller from the printing plate automatic inking and improve the operating speed, the aircraft and is equipped with manual and electric phase of the phase two, 360-degree adjustment phase, the ink not to dry and condensation, improved network roll and rubber roll life. Is ideal for carton industry and advanced printing equipment.

Printing Effect of Carton box making machine

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved