Function

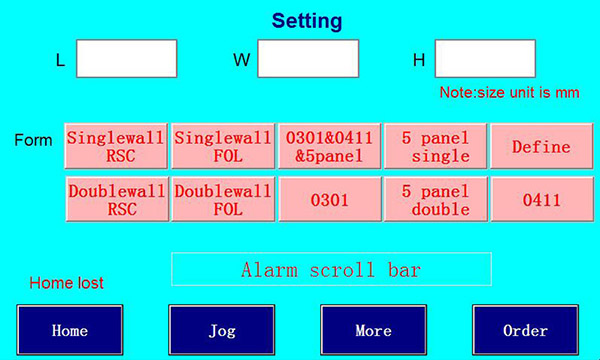

Application: for carton & cardboard manufacturer. Advantages: this machine is PLC+HMI control, can finish pre-pressing, slitting, scoring, trimming in one time pass. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency. Operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. Memory: save 300 orders | Manual feeder Auto adjusted slitter Auto adjusted pre-scorer and scorer Auto/manual blade grinder Auto adjusted pressure Jog function for fine-adjusted User-defined function Auto counter Slitting and scorer Precision ±0.5mm |

SPECIFICATIONS

No. | Model | ZBFY-AD2500 | |

1 | Blade/scorer | 4blade 6scorer | 5blade 8scorer |

2 | Feeder | Manual | |

3 | Pressure adjust | Auto | |

4 | Max. speed | 180m/min | |

5 | Max. feeding width | 2600mm | |

6 | Max. slitting width | 2500mm | |

7 | Min. slitting width | 190mm | |

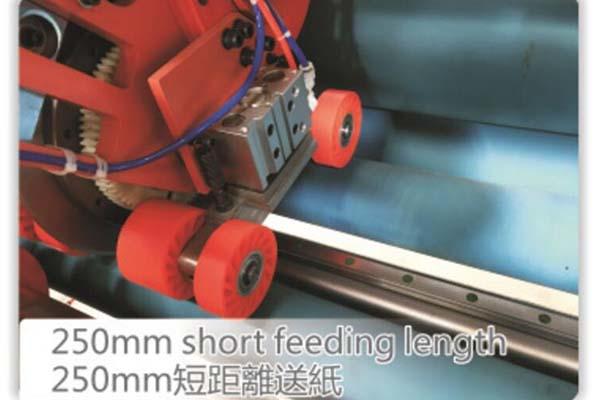

8 | Min. feeding length | 250mm (1for1: 480mm) | |

9 | Min. scoring width | 40x140mm | |

10 | Sheet thickness | 2-7mm | |

11 | Air pressure | 0.4Mpa | |

12 | Main motor power | 4kW | 5.5kW |

13 | Dimension(LxWxH) | 1570x3450x1500mm | |

14 | Overall net weight | 2500kg | 2800kg |

DESCRIBE

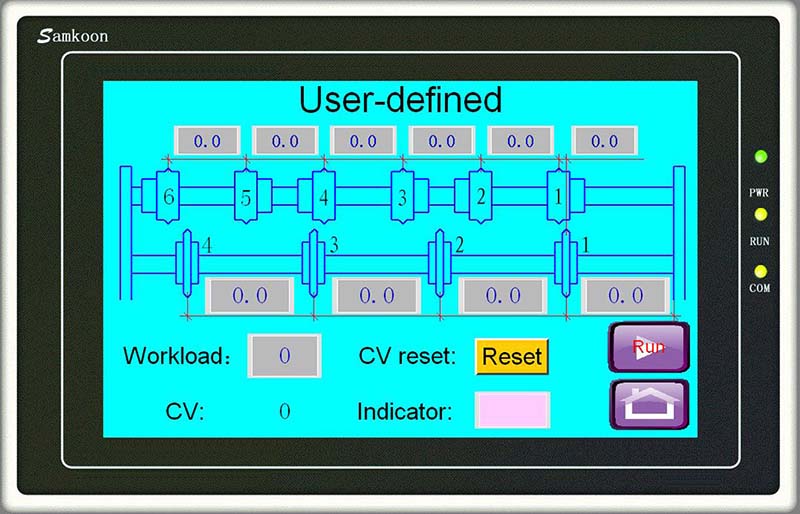

Operation HMI for Main machine

If you have some special work, can use this User-defined function

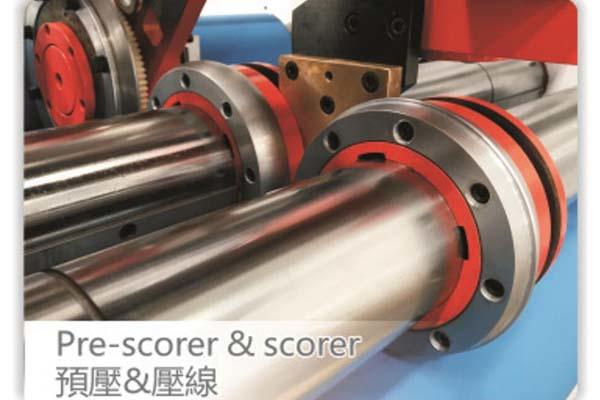

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

After-sales service

● Thanks to developed internet and after-sales network, communication become more and more convenience.

● The reliability of our machines make problem solving much easier, 99% of technical problem can be solved via remote assistance.

● Whenever customer need assistance or ask questions can communicate with the sales staff online, real-time to solve the problem, we are able to provide a full spectrum of services and prompt support.

Production Name:

XMY002-C Duplex shaft automatic Baloney Slitter,Baloney Tape Slitter, adhesive tape log roll cutting machine

This roll cutting machine is also suitable for fabric, non woven, cloth, adhesive films. etc .

More photo:

Cutting photo:

Feature:

1. Main driving part: AC motor with frequency converter is employed.

2. Central control unit: programmable central control is used and various sizes can be set on the same shaft for automatic transfer and cutting.

3. Operating panel: all functions are operated on the 10.4" Taiwan EVIEW LCD touch panel.

4. Motor control system: the central control system is PLC programmable controller.

5. Cutting positioning system: controlled by Mitsubishi servo motor. The imported high precision ball screw is applied to set the size and the linear slide rail is to bear the load of the cutter seat.

6. Blade feeding positioning system: controlled by Mitsubishi servo motor, and the cutting speed is adjustable in three stages. The efficiency is improved and the best quality is guaranteed.

7. Auto angle adjustment of circular blade: Mitsubishi servo motor is used to calculate the circular blade angle and the angle change is subject to different materials (the angle change range is ±8°). The cutting angle is changed directly when the cutting surface is not smooth, so the efficiency is improved.

8. Quick shaft change system: three kinds of shafts are available and quick change of shafts is applied for different materials.

Optional Parts:

1. Other size cutting shaft: It can be made as per the required core I.D.

2. Cutting supporter: For supporting log roll when cutting core below 38mm.

3. Safety cover: To protect operator during the production which is compliant to the CE regulation.

Main Technical Parameters:

cutting width | 1.3M 1.6M |

min. cutting width | 1mm |

max. cutting O.D | 150mm |

cutting core O.D | 1 " - 3 " |

cutting precision | ±0.1mm |

After-service:

1. Warranty for machines is 12 months and lifetime maintence.

2. A promptly reply within 24 hours.

3. Free usage training before delivering machines in factory.

Our Factory photo:

Certification:

Our location:

Policy&Gurantee:

A.One year gurantee for key parts of machine.

B.Free technical support.

C.Free industry information consulting.

D.Material support.

F&Q:

Q.:Are you a factory or trading company?

A.: We are a factory and manufacturer.

Q.:How does your factory do regarding qaulity control?

A.:We pay much attention on quality controlling from very beginning to the very end. Fully check and test takes before shipment.

Q.:Where is your factory located? How can I visit there?

A.:Our factory located at Kunsha,China.You can fly to shanghai air port directly .We will arrange to pick you up from airport.

Q.:What’s service or guarantee can you offer?

A.: One year guarantee for key parts of machine;Machine installing and worker training service;Free technical support whole life;Material support

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved