INTRODUCTION

Case King CK25

3 Step quick set-up | ||

1. Choose box type | 2. Input carton information | 3. One button setting |

Introduction The Case King model. CK25 is one of the most advanced box making machine available today. It is designed to solve the problem of small and medium orders of corrugated boxes quickly and easily. All tools are controlled through the simple touch screen. Size change from one style and size of box to another in seconds. Whether you need to produce small gift boxes, large wraps, furniture box, or more complicated boxes, the Case King can make them all at the touch of a button. | ||

Function

Application:for carton manufacturer. Advantages:this machine is PLC+HMI control, can finish auto feed, slot, cross score, angle cut, trim, H-cut, die-cut in one time pass. Special H-slot&score structure, can do small, medium and oversize carton. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency, it is a effective solution for small quantity order. | Easy operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. |

SPECIFICATIONS

No. | Model | CK25 | CaseKing |

1 | Max. Feeding size (WxL) | 2500mm x unlimited | horizontal slotting, max length can be unlimited |

2 | Min. feeding size (WxL) | 120 x 350mm | The min size can go through |

3 | Slotting width | 7mm | Slotting blade width |

4 | Max. slotting depth | 500mm | Slotting blade length |

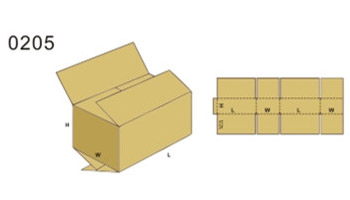

5 | 02xx Max. box height | 1600mm | Max. size between left and right slotting blade |

6 | 02xx Min. box height | 100mm | Min. Size between left and right slotting blade |

7 | Max. angle cutting width | 45mm | Angle blade length |

8 | Feeding thickness | 2-11mm | Gap between feeding rollers |

9 | Speed | 400-600pcs/h | Average speed |

10 | Air pressure | 0.3-0.6Mpa | |

11 | Total motor power | Abt. 15kW | |

12 | Dimension (WxLxH) | 3350x3700x2000mm | main machine size, if 2 unit will be less |

13 | Overall net weight | Abt6000kg | Total weight if 2 unit will be less |

Cardboard ≤ 700gsm

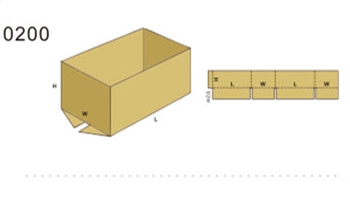

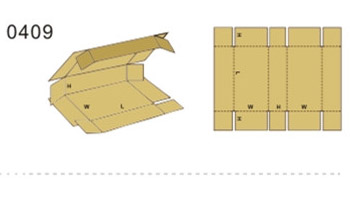

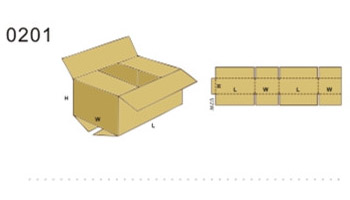

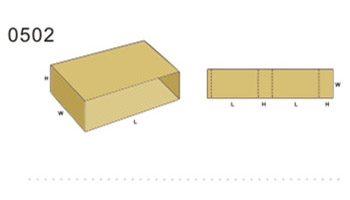

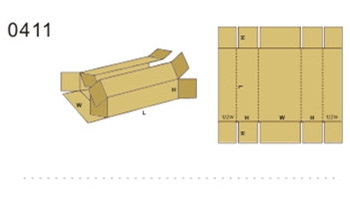

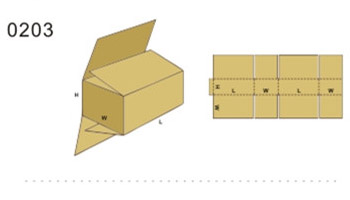

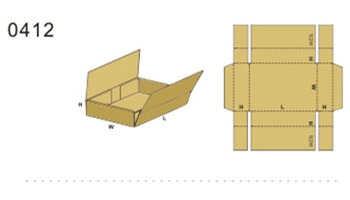

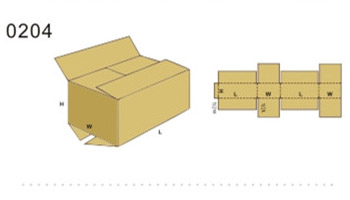

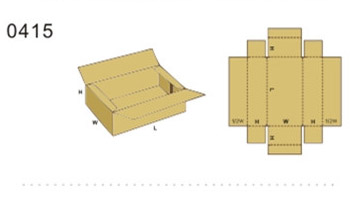

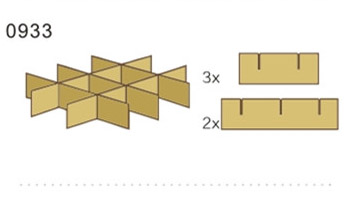

BOXES ACCORDING TO FEFCO (in one pass)

CK25 can also produce box type as follow: (without manual scorer)

● 0301,0452,0453,0911 can use 300

● 0458 can use 0302

● 0900,0902,0903 can use 0901

● 0930,0931,0932,0934,0935 can use 0933

● Define one pass:0228,0230,0231,0454,0455,0904,0905,0906,0907,0908,0909,0910,0913,0914,0920,0940,0942,0945,0946

● Define two pass:0208,0210,0212,0214,0229,0400,0403,0413,0420,0456,0921,0941,0943,0944

● Combination box:0306,0310,0312,0313,0320,0325,0331,0404,0405,0504,0505,0507,0509,0510,0512,0601,0607,0608,0610,0615,0616,0620,0621,0929

Automatic Carton Box Making Machine Prices

--printing slotting die cutting

Specification:

Data / Model | GSYM1220 |

Forme roller dia. | 405 (forme thickness 7.2mm) |

Forme roller length | 2000mm |

Max. mechanical design speed | 140sheets/min |

Economic running speed | 120 sheets/min |

Max. feeding size(mm) | 1200×2000mm |

Max. printing area(mm) | 1100×1950mm |

Min. feeding size(mm) | 400×650mm |

Paperboard thickness(mm) | 2-11mm |

Thickness of printing plate(mm) | 7.2mm |

Machine wall thickness | 50mm |

Overprint accuracy | ≤ ±0. 75mm |

Die cutting accuracy | ≤ ±1.0mm |

Main motor powder | 15 KW/18.5KW/22KW/37KW |

S/N | Item | Q'ty |

1 | Lead edge feeding unit | 1 set |

2 | Printing unit, assembly as follows: | 4 sets |

2.1 ceramic anilox roller 4sets | ||

2.2 Double doctor Blade chamber System 4sets | ||

3 | Die cutter withspeed compensator with servo transmission | 1 |

4 | Computer control system | 1 |

5 | Automatic stripping and stacker | 1 |

Details:

Functions and features

Functions and features

1The whole machine computerized PLC control, convenient and reliable.

2All driving rollers are high grade steel, plate with the hard chromium, abrade outside.

3Drive gear adopt 20CrMoTi high grade alloy steel to grind the day after tomorrow but becomes and goes through 60 degree of heat treatment Rockwell hardness greater than.

4 Each unit electrically departing, pneumatic locking, pneumatic general locking, sustained bell warning during moving, ensures operation personnel safe.

5 Different start and stop warning rings.

6 Start the machine by both hands, ensures that handling person safe.

7In front, middle and the end, there are emergency stop buttons.

8There are different guiding lights for switching-on, standby, moving and abnormal (three-color guiding lights of LED).

9 There are emergency stop buttons in each unit which can stop the moving of the unit inside to ensure the operators safe.

10Adopting ceramic anilox rollers and double doctor blade chamber system

11 Adopting int'l famous brands electric fittings for the whole machine. The complete machine zeroes without exception , wipe printing plate memory and preset function, printing and die-cutting phases zero, pre-adjustment and accurate adjustment, phase adjustment, all above make the whole machine with much higher accurate.

Characteristics of each unit

A. Feeding section

1) Main control panel consists of touch screen, VFD controller and buttons, convenient and reliable.

2) Main motor switching-on is controlled by double buttons which ensure the safety of the operators and the main machine.

3) Continuous and skip feeding (with counter) (choosing skip feeding if necessary).

4) Paperboard feeding counting setting, displaying production quantity.

5) Left and right baffles are controlled by motor-driven with gauge display.

6) The gap of the front baffle is adjusted manually. And there are dust-removing brushes at the rear of the baffle to clean the dust and miscellany and improve the printing quality.

7) Four shafts front edge feeding motor 11.0Kw, auxiliary suction feeding, can adjust the suction strength as per the warping degree of the paperboards to ensure smooth feeding.

8) Upper feeding roller outer dia. 149 mm, coated with anti-wear rubber which can avoid to press down the paperboard.

9) Lower feeding roller outer dia. 149mm, chrome coat with anilox.

10) Cross slide block coupling transmission to decrease abrasion and make transmission much more stable.

11) Electromotive control clutch, and with continuous alarming while moving to ensure the operators safe.

12) Driving shaft with electromagnetic abrasion clutch to avoid faulty operation or protect motors while overload.

13) Automatic return to zero in Feeding, printing and die cutting sections.

14) Air pressure interlocking devices.

B. Printing units

1. Forme roller

1) Forme roller outer dia. 390.6mm (405mm including the forme)

2) Printing roller with fine grinding and chrome coated.

3) Balancing correction, stable running.

4) Forme-hanging device, single side locking, accurate, convenient and fast.

5) Forme-hanging groove at the whole forme, suitable for 10mm forme-hanging slices.

6) Foot switch electromotive control the rotation making it easy to mount and disassemble the forme.

2. Print-pressing roller

1) Outer dia. of the print-pressing roller 130mm.

2) Fine grinding with chrome coated.

3) Balancing correction, stable running.

4) Self-locking device for the gap adjustment, adjusting range 0-11mm.

5)

3. Ceramic anilox rollers(180LPI – 700LPI optional).

1) Anilox roller dia. 187.57mm.

2) ceramic material.

3) Even ink applying, lengthen the life of the forme and the rubber roller.

4) Air pressure automatic lifting gear match the feeding section (the anilox roller descends to contact with the forme while printing, and the anilox roller lifts to depart from the forme while stopping printing).

5) Double doctor blade chamber system

Doctor blades form a sealed chamber with the ink inside,promote the printing quality with excellent inking quality (much better than the rubber roller inking system). It can save much ink during the printing process. Automatic clear system for the anilox rollers and doctor blade.

China famous brand.

C. Die cutting section

Accuracy of die cutting: ±1.0mm

1) The die roller and the anvil roller will separate automatically via cylinder eccentric device while not die cutting, which can decrease the idle load and lengthen life of the anvil and the die.

2) Plant-type gear structure, the same as that in printing section.

3) PLC control and 360 degree electric and digital adjustment for the die cutting phases.

4) Electric digital transverse movement, range: 10mm.

5) with the anvil correction device which can make the anvil roller to be used repeatedly.

2. die roller (lower roller)

1) Outer dia. 360mm, not including the die.

2) Cast with fine grinding and hard chrome plated

3) Balancing correction, stable running.

4) The hole distance of the fixing screw for the die, axial direction: 100mm, radial: 20 aliquot.

5) Knife height: 25.4mm.

Wooden die plate thickness: 16-18mm (for 3ply corrugation paperboard)

17-15.3mm (for 5ply corrugation paperboard)

3. Anvil roller (upper roller)

1) Outer dia. 384mm.

2) Alloy steel with fine grinding and hard chrome plated.

3) Balancing correction, stable running.

4) Manual adjustment the gat with the die.

5) Anvil thickness 10mm, width 250mm, normal life: 8 millions times cutting.

6) Mechanical transverse movement 50mm.

Working Video Available: Feel free to contact us

Our Warehouse:

We also sell:

Package and Shipping:

1.When we get your inquiry, we’ll recommend you the exact suitable machine for you.

2.We’ll reply to your email within 12 hours

3.We provide responsible and complete after-sales service.

4.Technical support, we can offer video for debugging

3.By the way,We can purchase packging film for you, according to your needs and requirements.

About warranty:

1.one year warranty,within warranty period ,we will provide free parts for replacement,if any problem belongs to us (delivery cost paid by customer)

2.if there are any malfunction for the machine.we will try our best to solve the problem within 24 hours

3.We can provide installation and maintenance service at your place if you need.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved