Company Advantages1. Every material used to manufacture Jingou Packaging Machinery cardboard core cutter has been screened fully and tested strictly to ensure it is 100% qualified. This product gives companies the ability to reliably package and ship right-sized orders

2. The product has been extensively applied in many industries because it can replace human to finish the repeated, tedious, or even dangerous tasks. Its well-designed casters improve its portability

3. The product dehydrates the food effectively within a short time. The heating elements in it heat up quickly and circulate the warm wind around inside. Thanks to its high-speed motor, this product can quickly achieve a satisfying stacking effect

4. The product is built to last. It provides adequate cushioning and has additional layers of padding for absorbing most of the impacts. It can speed up the corrugated box production, reducing the reliance on packaging labors

5. The biggest advantage of this product is energy saving. It can make self-adjustment in accordance with the different pressure needed during production to reduce energy consumption. This product is highly adaptable to paper with different thicknesses

Introduction Auto feeder

Suction feeder, cardboard sheet feeding is smooth and steady. Side board is computer controlled, auto lateral adjustment. The feeder structure is simple and reliable, suitable for large quantity of production orders, easy to maintain. |

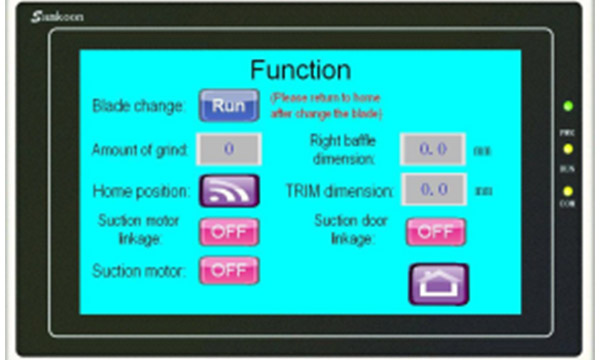

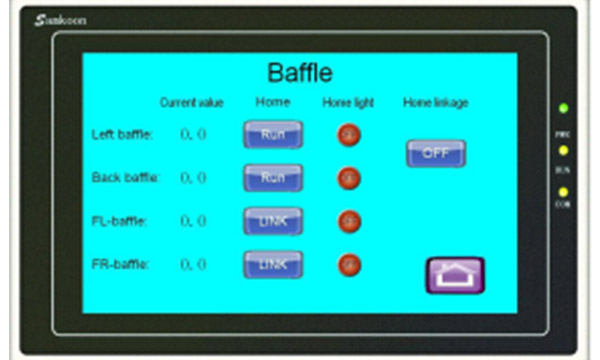

Function

Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

No. | Model | ZBFY-CD2500 | Unit |

1 | Blades & scorer | 4blade 6scorer | / |

2 | Feeder | Auto | / |

3 | Pressure adjustment | Auto | / |

4 | Speed | 160 | m/min |

5 | Max. feeding width | 2500 | mm |

6 | Max. slitting width | 2500 | mm |

7 | Min. slitting width | 200 | mm |

8 | Min. feeding length | 280 | mm |

9 | Min. scoring width | 40x140 | mm |

10 | Feeding thickness | 2-7 | mm |

11 | Air pressure | 0.4 | Mpa |

12 | Main motor power | 5.5 | kw |

13 | Dimension(LxWxH) | 2170x3450x1500 | mm |

14 | Overall net weight | Abt 3800+1500 | kg |

Cardboard ≤ 700gsm

Operation HMI for Auto feeder

Auto Thin Blade Slitter Scorer ZBFY-CD2500

● Auto feeder

● Auto adjusted slitter

● Auto adjusted pre-scorer and scorer

● Auto/manual blade grinder

● Auto adjusted pressure

● Jog function for fine-adjusted

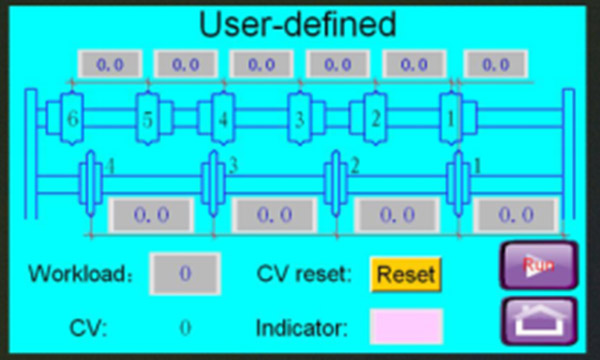

● User-defined function

● Auto counter

● Slitting and scorer Precision ±0.5mm

Operation HMI for Main machine

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

Company Features1. Jingou Packaging Machinery Co., Ltd. has an industry-leading research and development team.

2. We strive to make our business activities socially sustainable. We will earnestly implement our environmental protection plans. For example, we will upgrade the waste treatment efficiency, introducing advanced manufacturing machines that are more efficient in resources utilization.