Company Advantages1. The design of Jingou Packaging Machinery corrugated box machine is developed using a 3D CAD program. CAD models are created for the individual parts and the subassembly showing how the parts are connected together.

2. With our performance objective, the performance of this product is ensured by a series of tests.

3. Our professional quality check team conducts strict quality inspections for the sake of high quality.

4. The use of this product makes workers encounter lesser fatigue and tiredness. It greatly helps reduce the workload of workers.

5. This product brings about productivity gains and helps to maximize the use of available equipment and workers during production.

Case King CK25

3 Step quick set-up |

1. Choose box type | 2. Input carton information | 3. One button setting |

Introduction The Case King model. CK25 is one of the most advanced box making machine available today. It is designed to solve the problem of small and medium orders of corrugated boxes quickly and easily. All tools are controlled through the simple touch screen. Size change from one style and size of box to another in seconds. Whether you need to produce small gift boxes, large wraps, furniture box, or more complicated boxes, the Case King can make them all at the touch of a button. |

Function

Application:for carton manufacturer. Advantages:this machine is PLC+HMI control, can finish auto feed, slot, cross score, angle cut, trim, H-cut, die-cut in one time pass. Special H-slot&score structure, can do small, medium and oversize carton. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency, it is a effective solution for small quantity order. | Easy operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds.

|

No. | Model | CK25 | CaseKing |

1 | Max. Feeding size (WxL) | 2500mm x unlimited | horizontal slotting, max length can be unlimited |

2 | Min. feeding size (WxL) | 120 x 350mm | The min size can go through |

3 | Slotting width | 7mm | Slotting blade width |

4 | Max. slotting depth | 500mm | Slotting blade length |

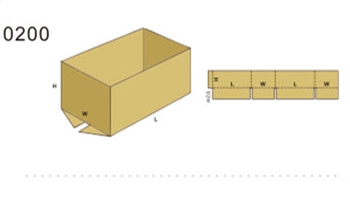

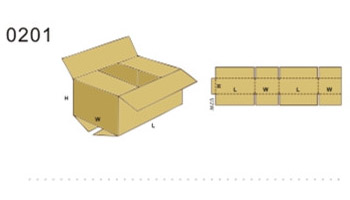

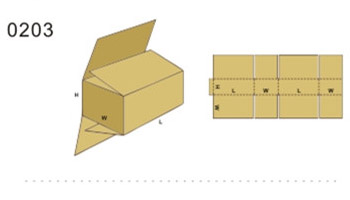

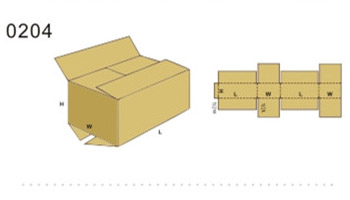

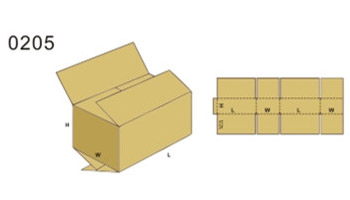

5 | 02xx Max. box height | 1600mm | Max. size between left and right slotting blade |

6 | 02xx Min. box height | 100mm | Min. Size between left and right slotting blade |

7 | Max. angle cutting width | 45mm | Angle blade length |

8 | Feeding thickness | 2-11mm | Gap between feeding rollers |

9 | Speed | 400-600pcs/h | Average speed |

10 | Air pressure | 0.3-0.6Mpa |

|

11 | Total motor power | Abt. 15kW |

|

12 | Dimension (WxLxH) | 3350x3700x2000mm | main machine size, if 2 unit will be less |

13 | Overall net weight | Abt6000kg | Total weight if 2 unit will be less |

Cardboard ≤ 700gsm

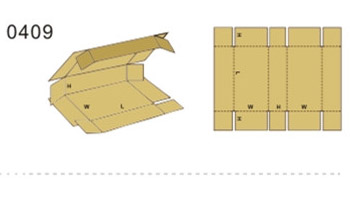

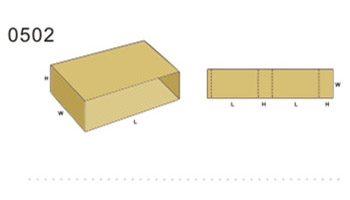

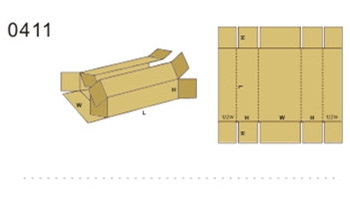

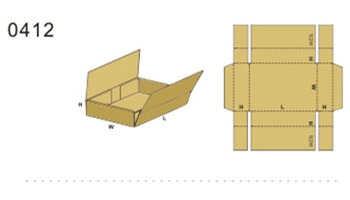

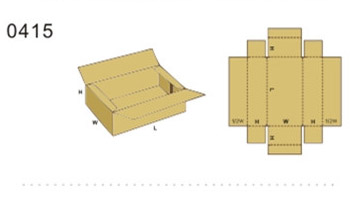

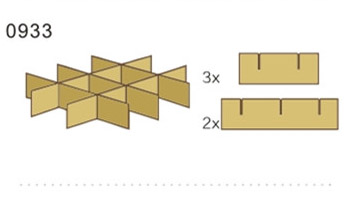

BOXES ACCORDING TO FEFCO (in one pass)

CK25 can also produce box type as follow: (without manual scorer)

● 0301,0452,0453,0911 can use 300

● 0458 can use 0302

● 0900,0902,0903 can use 0901

● 0930,0931,0932,0934,0935 can use 0933

● Define one pass:0228,0230,0231,0454,0455,0904,0905,0906,0907,0908,0909,0910,0913,0914,0920,0940,0942,0945,0946

● Define two pass:0208,0210,0212,0214,0229,0400,0403,0413,0420,0456,0921,0941,0943,0944

● Combination box:0306,0310,0312,0313,0320,0325,0331,0404,0405,0504,0505,0507,0509,0510,0512,0601,0607,0608,0610,0615,0616,0620,0621,0929

Company Features1. Jingou Packaging Machinery enjoys a good reputation for its corrugated box machine .

2. We have been certified under the ISO 9001 international management system. This system guarantees an efficient management process in place to monitor the production process and opens the door for continuous improvement.

3. We are devoted to delivering an amazing client experience. We will continue to strive toward mastery in everything we do leads to successful customer relationships. Our company bears social responsibilities. Sustainability is best addressed when it is coordinated across departments and built into key personnel's understanding of their job responsibilities. Our mission is to provide global leadership to create an environment beneficial to the sustainable and profitable growth of this industry to best serve our customers. Our ultimate goal is to achieve balanced development between humans and nature. We are piloting a production way that focuses on eliminating waste, reducing and controlling pollution.

| Packaging |

| | 123 (L) * 456 (W) * 789 (D) |

| | 1.2 T |

| | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

| Packaging |

| | 123 (L) * 456 (W) * 789 (D) |

| | 1.2 T |

| | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

High Speed Printing Slotting Die Cutting Machine (Front Feeding)

Functions and characteristics:

1.The whole machine's electrical appliances and computer software all adopt international well-known brands, with stable and reliable quality, human-machine interface, computer order management and easy operation.

2.The wall panels and important parts of the whole machine are aged and tempered to eliminate the internal stress of the metal. They are all made by high precision machining center and grinded by NC grinder.

3.The whole machine shaft and roll are made of high quality steel, grinding, high precision computer dynamic balance correction, and hard chromium plating on the surface.

4.The transmission gears of the whole machine are all made of 20CrMnTi alloy steel, carburized and quenched, with hardness HRC58-62. After grinding, the 6-level accuracy ensures the high accuracy of color matching for long-term use.

5.The whole machine transmission parts (shaft, teeth connection), are keyless connection (expansion sleeve), eliminating the connection gap, suitable for long-term high-speed operation of large torque.

6.The transmission bearings and important transmission components of the whole machine are all made up of three domestic brands: "Havaro", which is easy to maintain and has longer service life.

7.The lubrication system of the whole machine adopts spray-type automatic lubrication and is equipped with double oil level balance system.

8.The whole machine adjusts the pre-position function, feeding paper, printing, slotting, die cutting, automatic zero, automatic memory reset.

9.Adjustment of working clearance of the whole machine, no wrench fast adjustment, fast and convenient adjustment.

10.The main engine adopts frequency conversion control, starting and running more smoothly, more energy-saving.

11.Selection: Ceramic mesh roll, pusher. Scraper ink fixing system.

12.Installed with ink shortage alarm device, real-time monitoring of the working status of the ink supply system.

1)Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Running in a high automatization and intellectualization,no pollution