INTRODUCTION

Case King CK25

3 Step quick set-up | ||

1. Choose box type | 2. Input carton information | 3. One button setting |

Introduction The Case King model. CK25 is one of the most advanced box making machine available today. It is designed to solve the problem of small and medium orders of corrugated boxes quickly and easily. All tools are controlled through the simple touch screen. Size change from one style and size of box to another in seconds. Whether you need to produce small gift boxes, large wraps, furniture box, or more complicated boxes, the Case King can make them all at the touch of a button. | ||

Function

Application:for carton manufacturer. Advantages:this machine is PLC+HMI control, can finish auto feed, slot, cross score, angle cut, trim, H-cut, die-cut in one time pass. Special H-slot&score structure, can do small, medium and oversize carton. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency, it is a effective solution for small quantity order. | Easy operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. |

SPECIFICATIONS

No. | Model | CK25 | CaseKing |

1 | Max. Feeding size (WxL) | 2500mm x unlimited | horizontal slotting, max length can be unlimited |

2 | Min. feeding size (WxL) | 120 x 350mm | The min size can go through |

3 | Slotting width | 7mm | Slotting blade width |

4 | Max. slotting depth | 500mm | Slotting blade length |

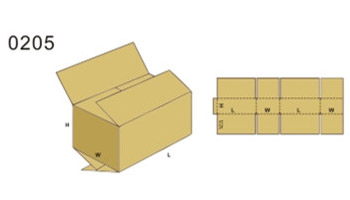

5 | 02xx Max. box height | 1600mm | Max. size between left and right slotting blade |

6 | 02xx Min. box height | 100mm | Min. Size between left and right slotting blade |

7 | Max. angle cutting width | 45mm | Angle blade length |

8 | Feeding thickness | 2-11mm | Gap between feeding rollers |

9 | Speed | 400-600pcs/h | Average speed |

10 | Air pressure | 0.3-0.6Mpa | |

11 | Total motor power | Abt. 15kW | |

12 | Dimension (WxLxH) | 3350x3700x2000mm | main machine size, if 2 unit will be less |

13 | Overall net weight | Abt6000kg | Total weight if 2 unit will be less |

Cardboard ≤ 700gsm

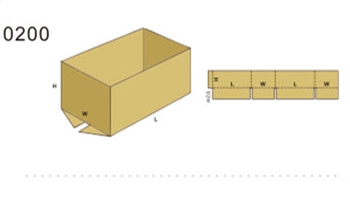

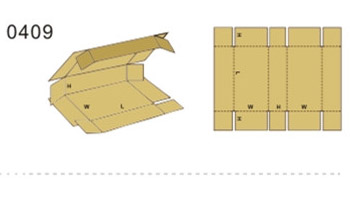

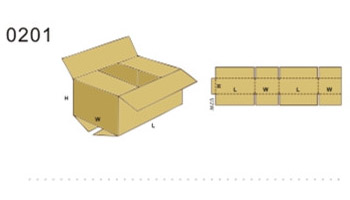

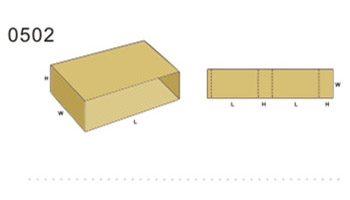

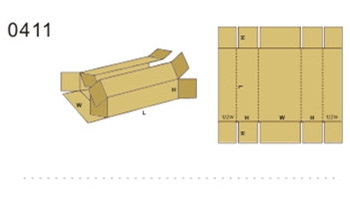

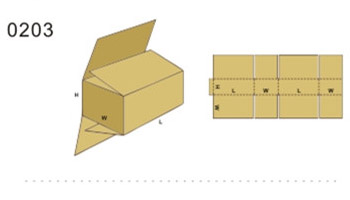

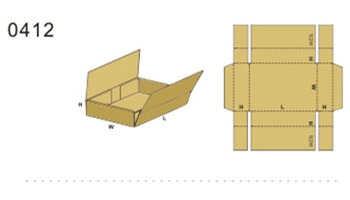

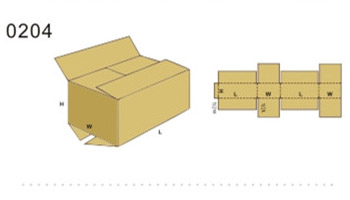

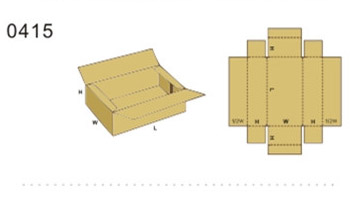

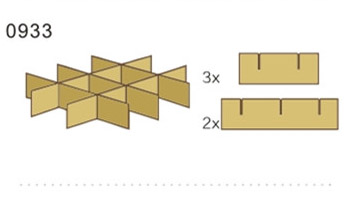

BOXES ACCORDING TO FEFCO (in one pass)

CK25 can also produce box type as follow: (without manual scorer)

● 0301,0452,0453,0911 can use 300

● 0458 can use 0302

● 0900,0902,0903 can use 0901

● 0930,0931,0932,0934,0935 can use 0933

● Define one pass:0228,0230,0231,0454,0455,0904,0905,0906,0907,0908,0909,0910,0913,0914,0920,0940,0942,0945,0946

● Define two pass:0208,0210,0212,0214,0229,0400,0403,0413,0420,0456,0921,0941,0943,0944

● Combination box:0306,0310,0312,0313,0320,0325,0331,0404,0405,0504,0505,0507,0509,0510,0512,0601,0607,0608,0610,0615,0616,0620,0621,0929

1. Automatic Cutting Machines for the packaging solutions.

BK PACK cutting system supplies the best solution to make sampling and short production run for packaging industries, and equipped with variety of knives and pens, and satisfies different kinds of material cutting. Such as Cardboard containers, corrugated cardboard, solid fibre board, synthetics..... It can connect with other software well with IECHO powerful data converting software, and complete the transition from traditional manual sampling to high precision.

2. Tool Type: Oscillating Knife, Creasing Wheel, Tangent Knife, Punching, V-CUT and pen.

3. Applicable material : Folding carton, corrugated board, white cardboard, grey cardboard, Polypropylene, foam inserts, paper-based sandwich board, printed corrugated and many other materials.

4. Effective Cutting Area:1300mm*1100mm, 1700mm*1300mm,1200mm*1600mm,2000mm*1100mm, 2500mm*1600mm and the size can be customerized .

5. Technicial Parameters:

It aims at solving the problem of small order with diverse styles and short lead time that the car seat cover factories are faced with.,thus meets the ever -changing consumption demand,helping the enterprise seize the business opportunity and increase their competitiveness.

With Wold-class design platform, it gurantees BK-L to become the leading leather cutting machine, combining with variety of professional tools, it can become a real high precision digital cutting system with simple upgrade, to realize through-cut, kiss-cut, carving, punching, creasing, drawing lines, etc. For leather, advertising, packaging, composite industries.

Name: Jenny Li

Cellphone / Whatsapp / viber : +8618738515992

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved