Introduction The Case King model. CS25+ is a semi-auto box making machine. It cost less, very easy to operate, is it designed to help carton manufacturer to solve the problem of small quantity orders quickly and easily. This model is the best selling machine. |

Function

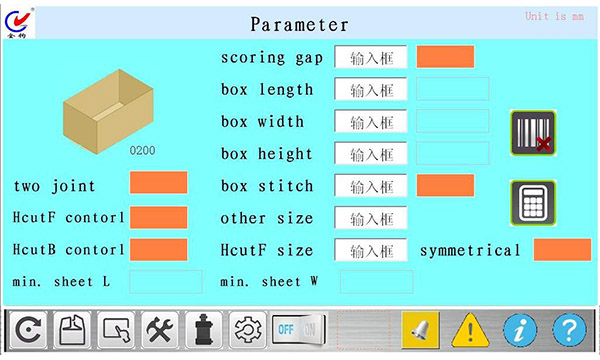

Application: for carton & cardboard manufacturer. Advantages: this machine is PLC+HMI touch screen control, can finish auto feeding, slotting, scoring, angle cutting, H-cut, v-cut, die-cut in one time pass. Special H-slot&score structure, can do small, medium and oversize carton. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency, it is a effective solution for small quality order. Easy operation: choose box type, input carton info, machine is ready to produce one carton or hundreds at the touch of a button. Both skillful operator and newcomer can control it well. Set up time: 1-30 seconds. | Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

SPECIFICATIONS

No. | Model | CS25+ | Semi auto CaseKing |

1 | Max. feeding size (WxL) | 2500mm x unlimited | horizontal slotting, max length can be unlimited |

2 | Min. feeding size (WxL) | 120 x 350mm | The min size can go through |

3 | Slotting width | 7mm | Slotting blade width |

4 | Max. slotting depth | 500/400/300mm | Slotting blade length |

5 | 02xx Max.box height | 1600/1800/2000mm | Max. size between left and right slotting blade |

6 | 02xx min box height | 70mm | Min. Size between left and right slotting blade |

7 | Max angle cutting width | 45mm | Angle blade length |

8 | Feeding thickness | 2-11mm | Gap between feeding rollers |

9 | Speed | 400-600pcs/h | Average speed |

10 | Air pressure | 0.3-0.6Mpa | |

11 | Total motor power | Abt. 15kW | |

12 | Dimension (WxLxH) | 4150x2000x1350mm | main machine size, if 2 unit will be less |

13 | Overall weight | Abt4500kg | Total weight if 2 unit will be less |

Cardboard ≤ 700gsm

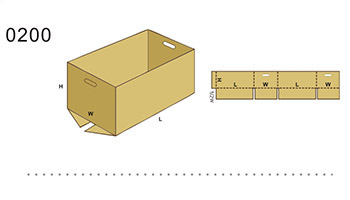

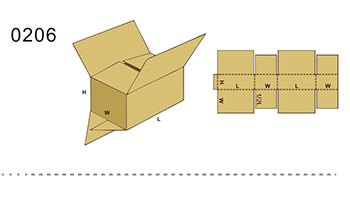

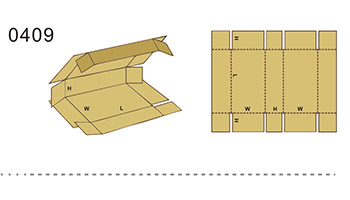

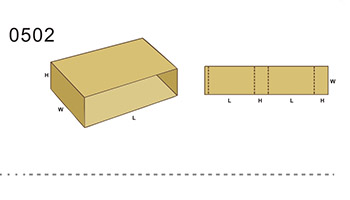

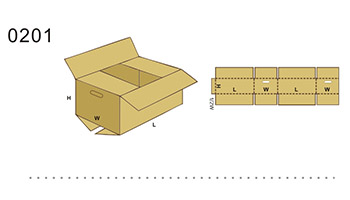

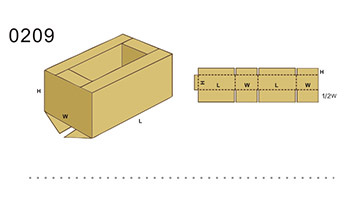

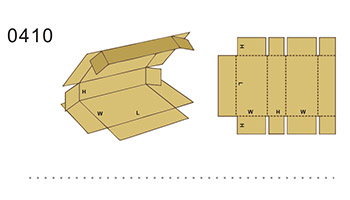

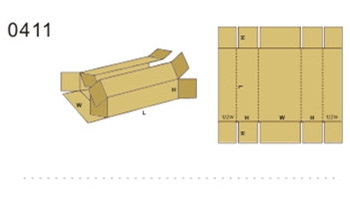

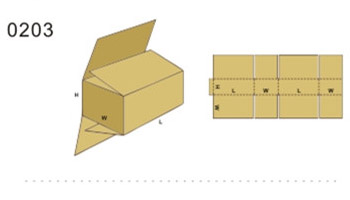

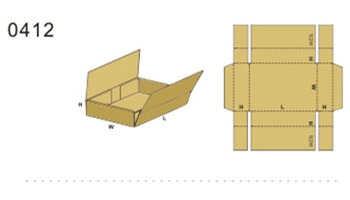

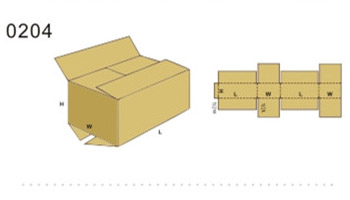

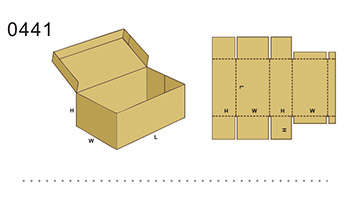

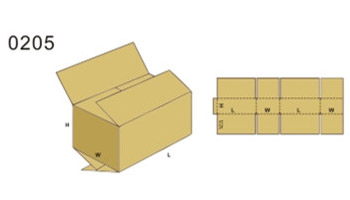

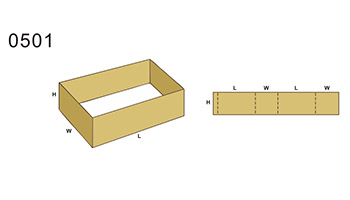

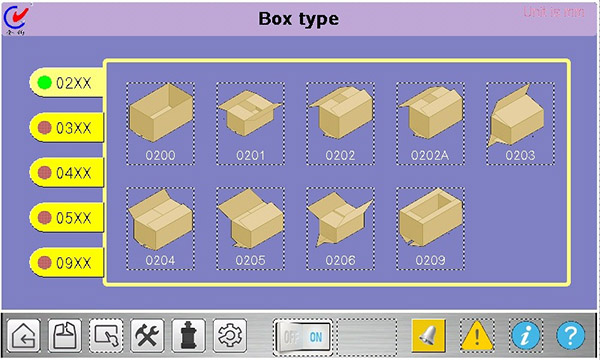

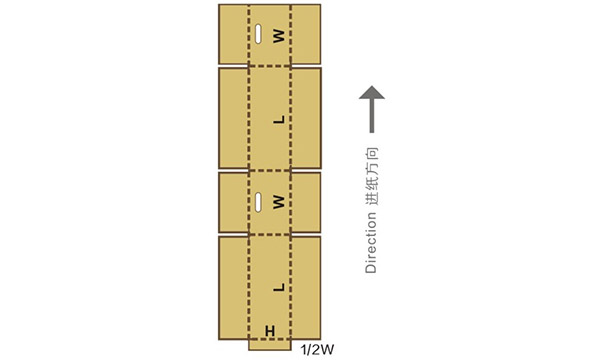

BOXES ACCORDING TO FEFCO (in one pass)

CS25+ can also produce box type as follow: (with manual scorer)

● 0301,0452,0453,0911 can use 0300

● 0458 can use 0302

● 0900,0902,0903 can us 0901

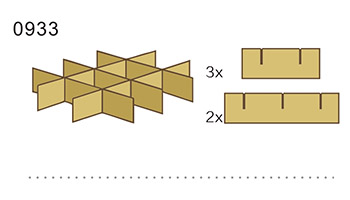

● 0930,0931,0932,0934,0935 can use 0933

● Define one pass:0214,0228,0229,0230,0231, 0403, 0413,0454,0455, 0904,0905,0906,0907,0908,0909,0910,0913,0914,0920,0940,0942,0945,0946

● Define two pass:0208,0210,0212,0400,0420,0456,0921,0941,0943,0944

● Combination box:0306,0310,0312,0313,0320,0325,0331,0404,0405,0504,0505,0507,0509,0510,0512,0601,0607,0608,0610,0615,0616,0620,0621,0929

DETAILS

(1). Operation HMI

a. 10 inch HMI |

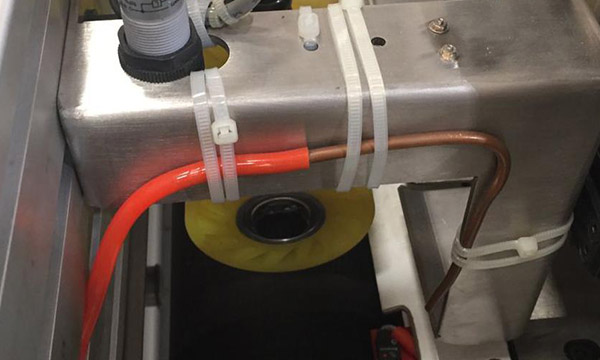

(2). Auto Feeder

a. Servo vacuum auto feeder system. |

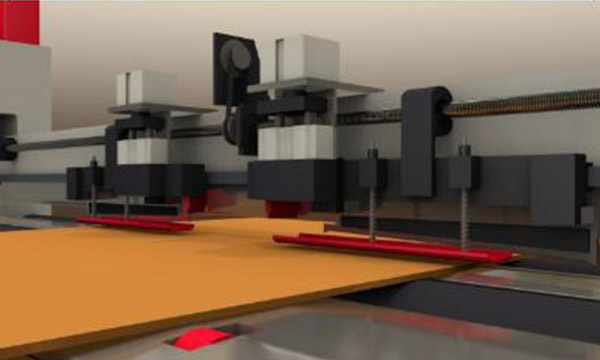

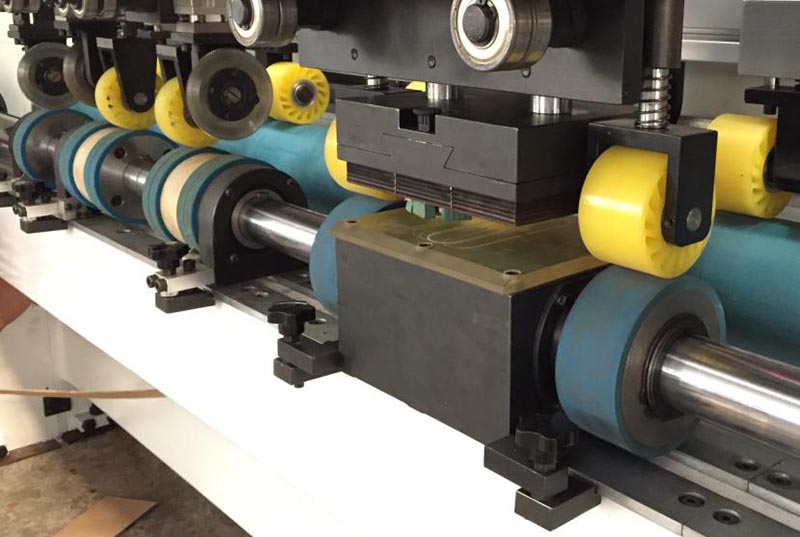

(3). H-slot&score

a. Distance between slot knives is 70-1600mm |

(4). Hcut

a. H-cut knife can cut front side, back side of cardboard sheet |

(5). V-cut & die-cut

a. 3 pcs of V-cut knife, one for trim, two for vertically cut. |

vacuum suction type fingerless single facer

Glue Rollers:

Diameter | Φ242mm |

Processing Way | Surface of glue roller is grinded, then with 25 line rut type net dot,then plating chrome Surface of glue banlance roller is grinded then plating chrome |

Control Way | Penumatic cylinder control of the Lifting Up-down |

Glue Supply | Glue circulating system(storage tank+glue pump) |

Corrugated Rollers:

Diameter | Down Roller:Φ320mm |

Material | 48CrMo high quality alloy steel, rigidity HRC55°-58° |

Processing Way | The surface of upper-lower roller is plating chrome, annealing, hardening and tempering, surface grinded |

Fulte Type | (U/V) ACBEF |

Material band or origin | Henan Jiyuan Iron & Steel Steel

|

Heating way of the reel paper | Steam heating |

Press Rollers:

Diameter | Φ324mm |

Material | medium steel (MS)45# |

Processing Way | The surface is grinded then plating chrome, hardening and tempering(With Buffer) |

Control Way | Penumatic cylinder control of the Lifting Up-down |

Material band or origin | Zhong Yuan Special Steel |

Preheater Rollers:

Diameter | UP Roller:Φ400mm |

Material | seamless steel tube |

Material band or origin | Tianjin Iron & Steel |

All connected by flexible metallic tubes | |

Common Spec:

Width of Paper | 1600mm/1800mm |

Style of Transmit cardboard | Vacuum Cover adsorbable style, Hight pressure Draw fan.with wind control Adjusting & noise deadening device. |

Style of Control Roller | Pneumatic control the upper roller, pressure roller and glue roller |

Lubrication | Anti-high temperature lube to lubricate the Corrugated Roller and Press Roller’s gears |

Driving Way:With frequency inverter | |

Wallboard & machine stand: cast iron,thickness:200mm | |

Common Spec:

Working width: 1600mm/1800mm

Operation Direction: Left or right (decided by the workshop of customer)

Design Speed: 150m/min

Temperature: 160—210℃

Air pressure: 1.0—1.3Mpa

Corrugated Flute Type: UV or UVV

Spec of Motor:

Main Motor: 7.5kw Nominal voltage: 380V 50Hz Continuous (S1) working Type

Fan Motor: 7.5kw Nominal voltage: 380V 50Hz Continuous (S1) working Type

1. What is the business of your company?

Henan Joinrise is specializing in designing and manufacturing of conveyor roller, conveyor pulley, conveyor idler, conveyor idler bracket. Our company has dedicated to the industry over 50 years.

2. What is the advantage of Joinrise compared to other suppliers?

Since the manufacturing team all possesses years of experience, Joinrise can provide conveyors and accessories with competitive price and superior service. We have professional sales team, production team, researching team.

3. What is the price policy of your company?

In our company, the price is different according to the quantity of your order, the more the cheaper. For more detailed information, you can contact our customer service representatives.

4. What are the features of the services your company offered?

Based on the wide product range, we offer the best One-Stop sourcing service and all-around after-sales service . We will definitely save you a lot of time and money. It will improve your efficiency significantly and be more economical.

5. What is the payment of your company?

Joinrise accepts the payment of T/T and L/C, 30%T/T in advance, 40% after shipment, the balance D/P,everything can be further discussed.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved