INTRODUCTION

Case King CK25

3 Step quick set-up | ||

1. Choose box type | 2. Input carton information | 3. One button setting |

Introduction The Case King model. CK25 is one of the most advanced box making machine available today. It is designed to solve the problem of small and medium orders of corrugated boxes quickly and easily. All tools are controlled through the simple touch screen. Size change from one style and size of box to another in seconds. Whether you need to produce small gift boxes, large wraps, furniture box, or more complicated boxes, the Case King can make them all at the touch of a button. | ||

Function

Application:for carton manufacturer. Advantages:this machine is PLC+HMI control, can finish auto feed, slot, cross score, angle cut, trim, H-cut, die-cut in one time pass. Special H-slot&score structure, can do small, medium and oversize carton. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency, it is a effective solution for small quantity order. | Easy operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. |

SPECIFICATIONS

No. | Model | CK25 | CaseKing |

1 | Max. Feeding size (WxL) | 2500mm x unlimited | horizontal slotting, max length can be unlimited |

2 | Min. feeding size (WxL) | 120 x 350mm | The min size can go through |

3 | Slotting width | 7mm | Slotting blade width |

4 | Max. slotting depth | 500mm | Slotting blade length |

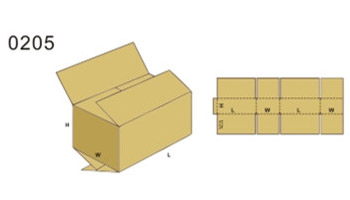

5 | 02xx Max. box height | 1600mm | Max. size between left and right slotting blade |

6 | 02xx Min. box height | 100mm | Min. Size between left and right slotting blade |

7 | Max. angle cutting width | 45mm | Angle blade length |

8 | Feeding thickness | 2-11mm | Gap between feeding rollers |

9 | Speed | 400-600pcs/h | Average speed |

10 | Air pressure | 0.3-0.6Mpa | |

11 | Total motor power | Abt. 15kW | |

12 | Dimension (WxLxH) | 3350x3700x2000mm | main machine size, if 2 unit will be less |

13 | Overall net weight | Abt6000kg | Total weight if 2 unit will be less |

Cardboard ≤ 700gsm

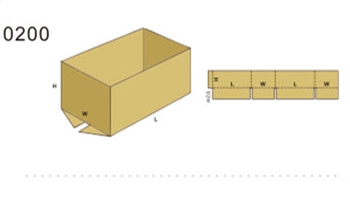

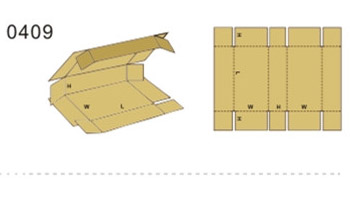

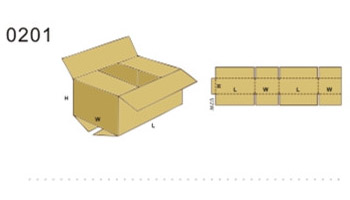

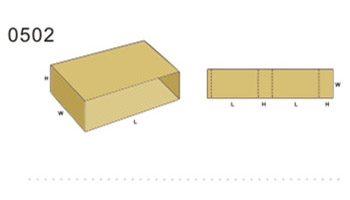

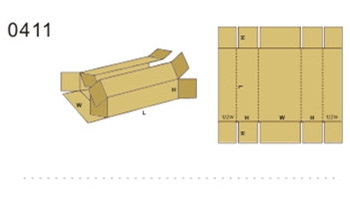

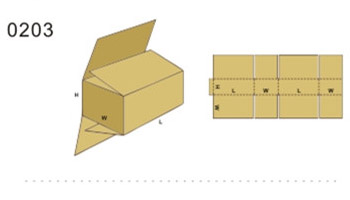

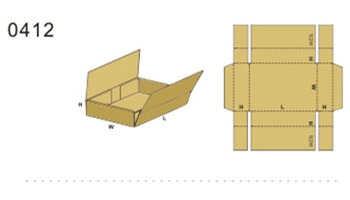

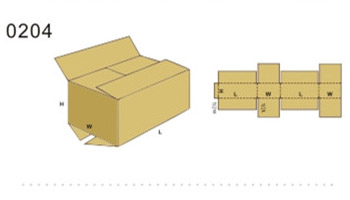

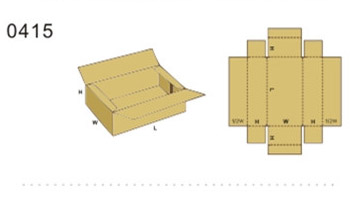

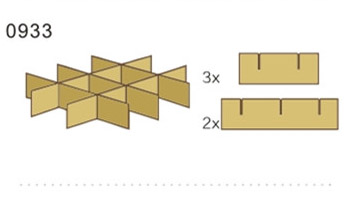

BOXES ACCORDING TO FEFCO (in one pass)

CK25 can also produce box type as follow: (without manual scorer)

● 0301,0452,0453,0911 can use 300

● 0458 can use 0302

● 0900,0902,0903 can use 0901

● 0930,0931,0932,0934,0935 can use 0933

● Define one pass:0228,0230,0231,0454,0455,0904,0905,0906,0907,0908,0909,0910,0913,0914,0920,0940,0942,0945,0946

● Define two pass:0208,0210,0212,0214,0229,0400,0403,0413,0420,0456,0921,0941,0943,0944

● Combination box:0306,0310,0312,0313,0320,0325,0331,0404,0405,0504,0505,0507,0509,0510,0512,0601,0607,0608,0610,0615,0616,0620,0621,0929

High Speed Flexo Printer Slotter Die Cutter Folder Gluer Corrugated Carton Box Making Machine Prices:

1. The machine is designed and made for high quality, high speed, high efficiency, high stability and high safety, convenient for quick order update and operation.

2. Made with high quality materials and parts.

3. Well hardened and ground transmission gears with hardness 50-55(HRC).

4. Auto zero return and auto reset.

5. All gaps between cylinders and rollers are computerized or motorized adjustment.

6. Key-free connection rings to reduce central wear, to keep stable precise printing.

7. All cylinders and rollers are hard chromed for ideal hardness.

8. Use imported PLC. PLC touch screen for multifunctional control.

9. Being able to save daily orders to speed up the order update.

10. Automatic Used Corrugated Carton Box Making Machine

YK Automatic Flexo Printing Slotting Die Cutting Folder Gluer Corrugated Carton Box Making Machine Prices:

YK Items | 1000x1800 1000x2000 1000x2200 | 1200x2200 1200x2500 1200x2800 | 1400x2200 1400x2500 1400x2800 | ||

Max. machine speed of lead edge feeder (p/min) |

220 |

220 |

200 | ||

Max. feeding size (mm) | 1000x1800 1000x2000 1000x2200 | 1200x2200 1200x2500 1200x2800 | 1400x2200 1400x2500 1400x2800 | ||

Min. feeding size (mm) | 320x600 | 360x650 | 400x650 | ||

Skip feeding (mm) | 1200x1800 1200x2000 1200x2200 | 1400x2200 1400x2500 1400x2800 | 1600x2500 1600x2800 1600x3200 | ||

Max. printing area (mm) | 950x1750 950x1950 950x2150 | 1150x2150 1150x2450 1150x2750 | 1350x2150 1350x2450 1350x2750 | ||

Printing precision (mm) | ±0.5 | ±0.5 | ±0.5 | ||

Printing plate thickness (mm) | 7.2 | 7.2 | 7.2 | ||

Min. slotting space | Normal knife (mm) Reverse knife (mm) | 160x160x160x160 320x60x320x60 | 180x180x180x180 360x80x360x80 | 180x180x180x180 360x80x360x80 | |

Max. slotting depth (mm) | 270 | 300 | 350 | ||

Slotting precision (mm) | ±1 | ±1 | ±1 | ||

Feeder Unit

1. Lead wheel feeding system. The servo motor is imported from Germany, which control easily and feed accurately.

2. Feeding with four-shaft-structure, the rubber is very wearable.

3. The main engine is frequency convertor, stable starting, prolong the machine’s life and save power.

4. The frequency convertor is used at the suction system, it can promise feeding accurately and adjusting easily.

5. Double feeding rollers, bumpers are used to promise feeding accurately, and equip the brush to clean dust.

6. Adjusting the feeding rollers’ gap by the LCD, adjusting range: 0-11mm.

7. 5.7 inch touch screen, it shows the production, speed and it can control the engine’s speed and the left –right boards.

8. Vacuum suction system. The air volume can be set in accordance with different paperboard bending conditions so as to feed paper smoothly.

Printing unit

1. Ceramic rollers.

2. Quick hanging forme device can save more time

3. Adjusting clearance of impressing roller by computer, and digital setting.

4. Printing phase is controlled by PLC and touch screen and can be reset electrically with 360 degree adjustment (no matter running or stopping), and being able to store orders.

5. Regulating printing phase position is motorized by planetary gear system and digital displays.

6. Transversal movement regulating by motor covers 20mm.

7. Auto zero return and auto reset.

8. 5.7 inch touch screen, controlling the phases.

9.Vaccum transfer

Slotting Unit

1. The above and below axes are equipped with four-shaft structure.

2. Transversal movement of slotting knife, pre-pressing wheel and creasing wheel are controlled by PLC and touch screen. Being able to store orders.

3. The structure of regulating slotting phase is planetary gear system.

4. Slotting phase is controlled by PLC and touch screen can be reset electrically with 360 degree adjustment (no matter running or stopping)

5. Controlling panel with 10.4 inches touching screen.

6. Pre-pressing wheel: after pre-pressing, cardboard can’t be damaged.

7. Auto zero return and auto reset. Controlling by PLC.

Option Die cutting Unit

1.Adopting synchronizer to make the speed of die cutting roller and rubber pad roller is consistent so as to improve the precision of die cutting, no matter rubber pad wears. So this can ensure the shape of the cutting cardboard are the same as the die cutting pattern.

2.Anvil roller (up roller): mechanical helix fluted-roll type, transverse movement 40mm.

3.Die cutting phase is controlled by PLC and touch screen can be reset electrically with 360 degree adjustment (no matter running or stopping)

4.Fitting with the rubber repair system to prolong service life and lower the cost.

5.Regulating die cutting phase position with planetary gear structure.

6.Transmission gears are made of 40CrMnTi.

Auto Folder Gluer | ||||

| ||||

1. | Folder Gluer Device | |||

1.1 | In-line control of printing unit, touch screen panel. | |||

1.1 | This machine adopts bottom folding system in-line with top printer to prevent adhesion rebound. | |||

1.3 | Adopts USA Haeco Gluing system, which is easy to operate, and save glue. | |||

1.4 | Air suction control of upper folding belts, right/left belts can be adjusted freely. | |||

1.5 | Position setting digitally control, and can be operated in each printing unit. | |||

2. | Counter Ejector Device | |||

2.1 | There is a space for temporary storage and flap after folding and gluing to ensure cartons well-glued and fixed. | |||

2.2 | Vacuum adsorption for paper-out, quick set, precise counting. | |||

2.3 | Stacking unit designed with elevation structure to protect carton damage, quantity pre-set, neat stacking, auto ejecting. | |||

2.4 | Position setting is digitally control. |

| ||

2.5 | Accurate counting/auto stacking/auto ejecting and can be easy match with bundling unit (Bundling unit - Optional). |

| ||

| Flexo Printing Slotting Die Cutting Folder Gluer Corrugated Carton Box Making Machine | ||||

We take part in the exhibition almost every year.Carton stripper is of high quality and reasonable price,Carton stripper is popular with the masses.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved