INTRODUCTION

Case King CK25

3 Step quick set-up | ||

1. Choose box type | 2. Input carton information | 3. One button setting |

Introduction The Case King model. CK25 is one of the most advanced box making machine available today. It is designed to solve the problem of small and medium orders of corrugated boxes quickly and easily. All tools are controlled through the simple touch screen. Size change from one style and size of box to another in seconds. Whether you need to produce small gift boxes, large wraps, furniture box, or more complicated boxes, the Case King can make them all at the touch of a button. | ||

Function

Application:for carton manufacturer. Advantages:this machine is PLC+HMI control, can finish auto feed, slot, cross score, angle cut, trim, H-cut, die-cut in one time pass. Special H-slot&score structure, can do small, medium and oversize carton. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency, it is a effective solution for small quantity order. | Easy operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. |

SPECIFICATIONS

No. | Model | CK25 | CaseKing |

1 | Max. Feeding size (WxL) | 2500mm x unlimited | horizontal slotting, max length can be unlimited |

2 | Min. feeding size (WxL) | 120 x 350mm | The min size can go through |

3 | Slotting width | 7mm | Slotting blade width |

4 | Max. slotting depth | 500mm | Slotting blade length |

5 | 02xx Max. box height | 1600mm | Max. size between left and right slotting blade |

6 | 02xx Min. box height | 100mm | Min. Size between left and right slotting blade |

7 | Max. angle cutting width | 45mm | Angle blade length |

8 | Feeding thickness | 2-11mm | Gap between feeding rollers |

9 | Speed | 400-600pcs/h | Average speed |

10 | Air pressure | 0.3-0.6Mpa | |

11 | Total motor power | Abt. 15kW | |

12 | Dimension (WxLxH) | 3350x3700x2000mm | main machine size, if 2 unit will be less |

13 | Overall net weight | Abt6000kg | Total weight if 2 unit will be less |

Cardboard ≤ 700gsm

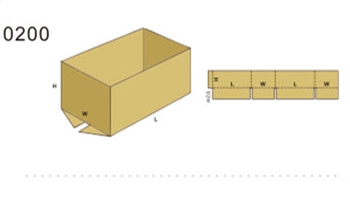

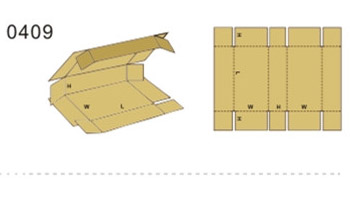

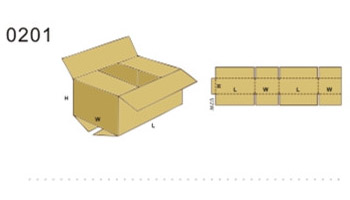

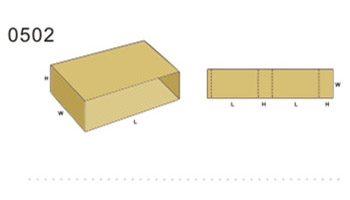

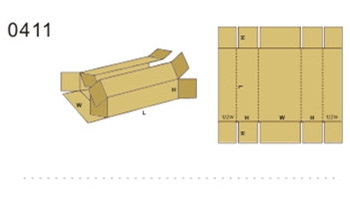

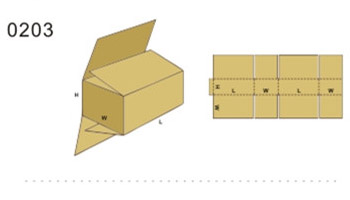

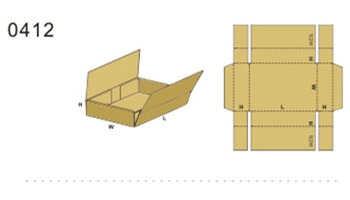

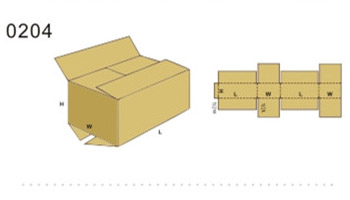

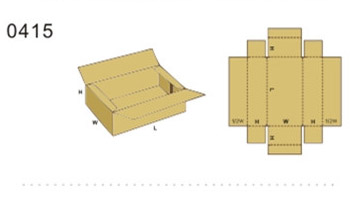

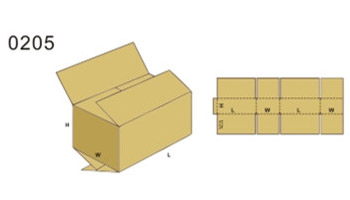

BOXES ACCORDING TO FEFCO (in one pass)

CK25 can also produce box type as follow: (without manual scorer)

● 0301,0452,0453,0911 can use 300

● 0458 can use 0302

● 0900,0902,0903 can use 0901

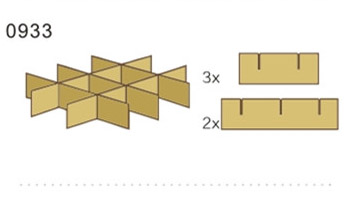

● 0930,0931,0932,0934,0935 can use 0933

● Define one pass:0228,0230,0231,0454,0455,0904,0905,0906,0907,0908,0909,0910,0913,0914,0920,0940,0942,0945,0946

● Define two pass:0208,0210,0212,0214,0229,0400,0403,0413,0420,0456,0921,0941,0943,0944

● Combination box:0306,0310,0312,0313,0320,0325,0331,0404,0405,0504,0505,0507,0509,0510,0512,0601,0607,0608,0610,0615,0616,0620,0621,0929

Fully automatic single facer corrugated carton box making line machine

Electrical Mill Roll Stand

Uses and Features:

1 .Electrical shaftless mill roll stand, which is used in corrugated cardboard production line,its fuction is supporting the paper mill roll.

2. Symmetrical structure can install two rolls of paper at the same time and continually change paper;

3.Paper roll clamp-loosen, lift-lower, movement, contraposition, translation ect operated by electric driven .

4.Maximum diameter:φ1600mm

5. Range of width: 1200mm-1800mm

6.pneumatic or mannual control web tension.

Taper center, stretch center is optional.

BL vacuum absorption type Single Facer

Uses and Features:

1.Design speed: 100m/min.

2.Effective Width: 1200mm-2000mm

3.The diameter of corrugated roller :280 mm

4 Type of Corrugated Roller A, B, C D, E,F,G

5.Cardboard transmit adopts vacuum suction method , with wind control system. Keep flute profiles stable of the lower-roller in the condition of running up.

6. The upper-lower corrugated roller are made of high quality 48CrMo alloy steel and heat-treatment. The rigidity is HRC58-60°,the surface are whetted.

7.Upper and lower corrugated roller are unit assemblage ,the whole corrugated rollers group can be move and quick replacement ,to change flute type quickly .

8. Drive decelerate box adopts oil immersed type lubricating to reduce noise. Keep running stable.

9.Single face Lift-lower of upper corrugating roller, pressure roller and glue roller are controlled by pneumatic control.

SINGLE CUTTER

Equipment performance:

Single cutter can do single corruagted cardboard vertically and horizontally cutting.It has Change order fast and high cutting precision,working speed fast etc.make little waster,when changed the order.It suit for the top grade colour prinitng machine.This machine adopt PLC touch screen to design .Through it operator can know all the production status. Adopt variable frequency motor to adjust the speed. Servo control make the cutting length more exactly, making the cutting precisiopn perfectly.(error±1.5mm).mechanical behavior will more fine.

| Working speed(m/min) |

|

|

1600 | 0-80 | A C B D E F | Electric/steam/gas |

Welcome to contact me to get full details and video!!!

Skype: zhaolicn77

Mob: +86-15031776803

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved