Introduction Auto feeder |

Function

Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

SPECIFICATIONS

No. | Model | ZBFY-CD2500 | Unit |

1 | Blades & scorer | 4blade 6scorer | / |

2 | Feeder | Auto | / |

3 | Pressure adjustment | Auto | / |

4 | Speed | 160 | m/min |

5 | Max. feeding width | 2500 | mm |

6 | Max. slitting width | 2500 | mm |

7 | Min. slitting width | 200 | mm |

8 | Min. feeding length | 280 | mm |

9 | Min. scoring width | 40x140 | mm |

10 | Feeding thickness | 2-7 | mm |

11 | Air pressure | 0.4 | Mpa |

12 | Main motor power | 5.5 | kw |

13 | Dimension(LxWxH) | 2170x3450x1500 | mm |

14 | Overall net weight | Abt 3800+1500 | kg |

Cardboard ≤ 700gsm

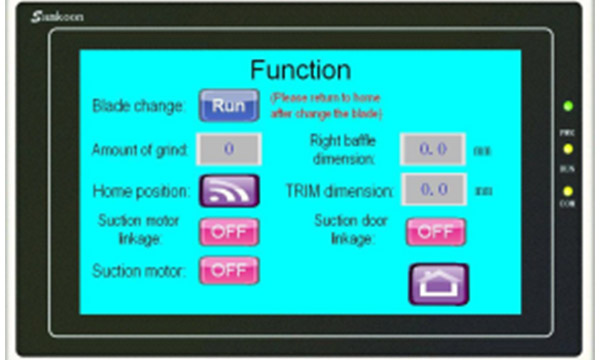

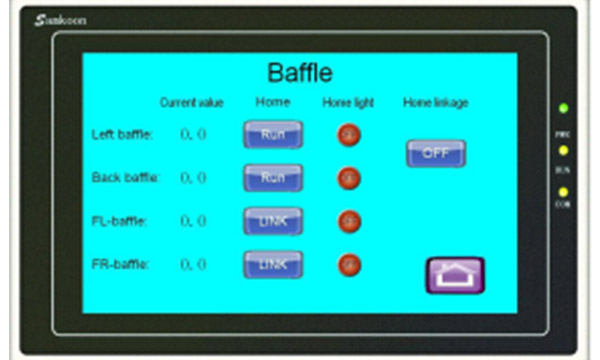

Operation HMI for Auto feeder

Auto Thin Blade Slitter Scorer ZBFY-CD2500

● Auto feeder

● Auto adjusted slitter

● Auto adjusted pre-scorer and scorer

● Auto/manual blade grinder

● Auto adjusted pressure

● Jog function for fine-adjusted

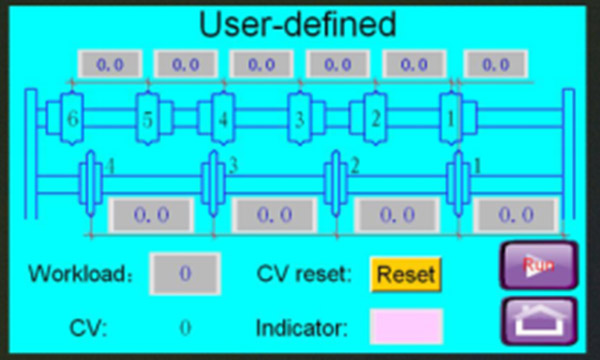

● User-defined function

● Auto counter

● Slitting and scorer Precision ±0.5mm

DETAILS

Operation HMI for Main machine

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

Corrugated Cardboard Box Making Machine

Specification:

| MWB1450Q | MWB1450 |

Max.paper size | 1480mm×1080mm | |

Min.paper size | 550mm×480mm | |

Max.cutting size | 1450mm×1050mm | |

Max.cutting pressure: | 300×104N | |

paper type | Corrugated paper 1-8mm, Cardboard 300gsm above | |

Die cutting precision | ±0.5mm | |

Max.mechanical speed | 4200sheets/h | 4000sheets/h |

Paper piled height | 1260mm | |

Paper feeding height: | 1100mm | |

Paper delivery height | 1423mm | |

Pressure adjusting range: | ±1mm | |

Minimum front margin: | Needle ≥10mm, gripper ≥8mm | |

Maximum wood plate size | 1480×1080mm |

|

Total power: | 21kw | 20.5Kw |

Machine dimension: | 7750×4860×2440mm (include the work platform, pre-feeder) | 6330x4900x2350mm (include the work platform, pre-feeder) |

5140×2605×2240 mm (exclude the work platform, pre-feeder, die change frame) |

| |

Gripper /Needle number/each | 11/18 | |

Total weight: | 19t | 17t |

Feature:

MWB1450Q is the classic series which adopt below function on the basis of semi-automatic die cutting machine, it is the initiate of home. Half-stripping system, automatic cleaning three side and middle part, Clean and greatly improves efficiency. Stripping Mold adopt central positioning system, automatic clipping, Upper Stripping mold adopt electric control lifting device

Details:

1)Main Chain drive:

The main driving system adopts crank and worm gear pair and special crank shaft linkage mechanism connect by bearing shell which can reduce locomotive gap, avoid impacting and ensure smooth running, pressure of die-cutting is high.

2)Touch screen:

3) Breakers:

4):Electrical control part:

PLC control is adopted in Electronic Control System. There are various safe guarding devices that when accident occurs, it will give an alarm by sound and light and shutdown automatically to protect safety of man and machine.

5)Die cutting and creasing:

The reliable overload protective mechanism can make the driving and driven parts separated automatically when overload accident occurs. The unique die-cutting frame can prevent the die-cutting plate from dropping and separating effectively.

6 Main Driving system:

7 stripping part:

Male and Female die can be inserted into the machine from operation side to shorten the set up time and for higher safety.

Centerline system compatible to centerline II for quick change over and short set up time

3 sides and middle parts was stripped to ensure more working efficiency

Working Video Available: Feel free to contact us

Finished Machine:

Our Warehouse:

We also sell:

Package and Shipping:

Our Company:

G&Z group is one of leading manufacturers specialized in laminating machines in China, our laminating machines are suitable for the color printed top sheet and corrugated paperboard, and have been installed all of the world, besides of the top machines' quality, we also have earned good reputation on our aftersales services.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved