Function

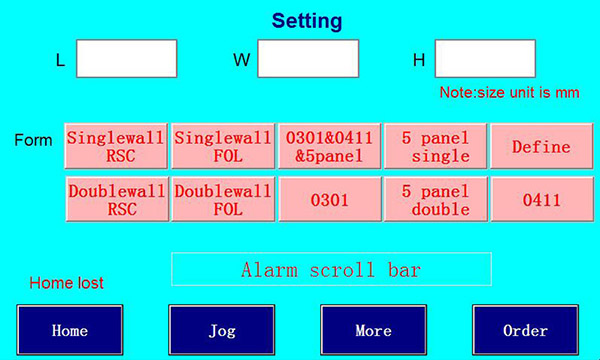

Application: for carton & cardboard manufacturer. Advantages: this machine is PLC+HMI control, can finish pre-pressing, slitting, scoring, trimming in one time pass. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency. Operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. Memory: save 300 orders | Manual feeder Auto adjusted slitter Auto adjusted pre-scorer and scorer Auto/manual blade grinder Auto adjusted pressure Jog function for fine-adjusted User-defined function Auto counter Slitting and scorer Precision ±0.5mm |

SPECIFICATIONS

No. | Model | ZBFY-AD2500 | |

1 | Blade/scorer | 4blade 6scorer | 5blade 8scorer |

2 | Feeder | Manual | |

3 | Pressure adjust | Auto | |

4 | Max. speed | 180m/min | |

5 | Max. feeding width | 2600mm | |

6 | Max. slitting width | 2500mm | |

7 | Min. slitting width | 190mm | |

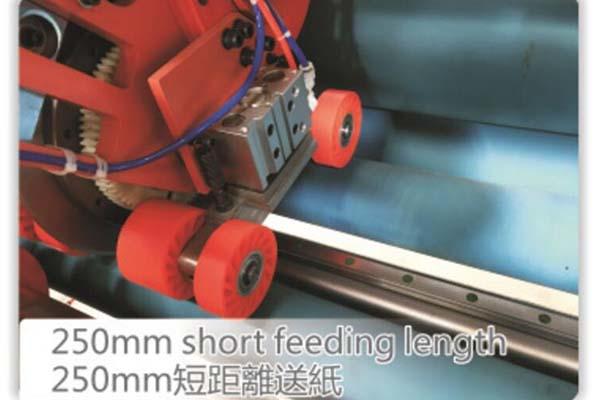

8 | Min. feeding length | 250mm (1for1: 480mm) | |

9 | Min. scoring width | 40x140mm | |

10 | Sheet thickness | 2-7mm | |

11 | Air pressure | 0.4Mpa | |

12 | Main motor power | 4kW | 5.5kW |

13 | Dimension(LxWxH) | 1570x3450x1500mm | |

14 | Overall net weight | 2500kg | 2800kg |

DESCRIBE

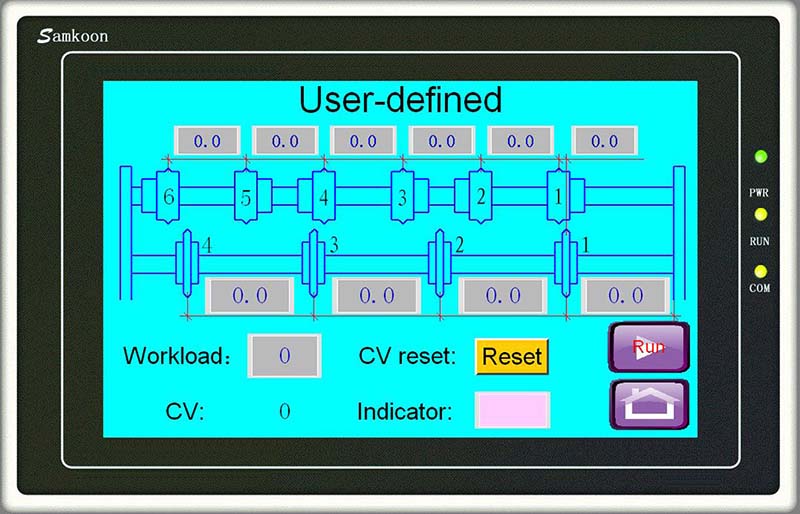

Operation HMI for Main machine

If you have some special work, can use this User-defined function

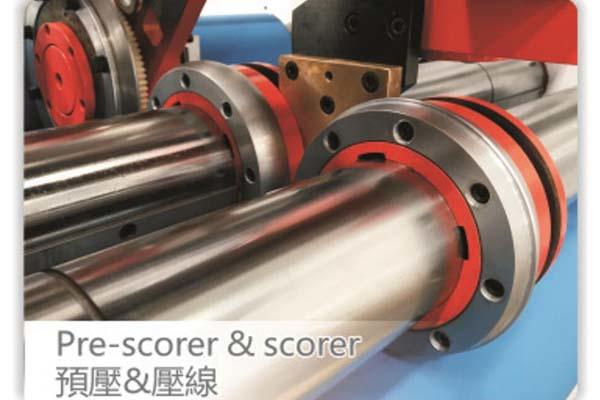

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

After-sales service

● Thanks to developed internet and after-sales network, communication become more and more convenience.

● The reliability of our machines make problem solving much easier, 99% of technical problem can be solved via remote assistance.

● Whenever customer need assistance or ask questions can communicate with the sales staff online, real-time to solve the problem, we are able to provide a full spectrum of services and prompt support.

adhesive tape log jumbo roll cutting machine

1.Machine function

the machine is used to cut all kinds of adheisve tape jumbo rolls

2.Machine specification

efficient width:1300-1600mm

max cutting diameter:400mm

min cutting width:1mm

paper core diameter:25.4-76.2mm

cutting precision:+/-0.1mm

diameter of circular blade:250/300/350/450

size:3000*1200*1550mm

3.Machine pics

4.customer pic

5.Workshop pic

6.certificate pic

7.Welcome your kind inquiry on our machines

wechat and whatsapp:008615931681161

skype:shirleywing69

QQ:1066379971

Suitable for cutting BOPP / PVC / PE /PET/ EVA / 3M/Mylar / masking /foam / cloth /double sticky /Kraft / aluminum duct tape / pretection film etc.

| Max. Cutting O.D | 400mm |

| Min. Cutting Width | 2mm |

| Cutting precision | +0.1mm |

| Cutting Core I.D | 1"-3" |

| Machine Width | 1.3M-1.6M |

Feature:

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved