Company Advantages1. Premium raw materials: Jingou Packaging Machinery cardboard creasing machine is made of durable and safe materials. These materials are carefully selected from reliable suppliers to ensure their longevity. Its well-designed casters improve its portability

2. The customers of Jingou Packaging Machinery will continue to enjoy the same service standards and warranties of core cutting machine . With its fully-automatic feature, this product helps reduce paper waste

3. Its electrostatic sensitive device has high electrostatic sensitivity, meaning this device can withstand much electrostatic discharge voltage. Its waste paper suction device helps maintain a clean production environment

4. The product is very durable. Made of hard materials, it is less likely to be affected or destroyed by any surrounding element. Its smart technology help achieve reductions in production downtime

5. It is eco-friendly and sustainable. Not any chemical substances or gases will release during the barbeque owing to the fact that the steel used in this product contains very limited harmful micro metallic elements. Equipped with an automatic board feeder, this product features high efficiency

Introduction Auto feeder

Suction feeder, cardboard sheet feeding is smooth and steady. Side board is computer controlled, auto lateral adjustment. The feeder structure is simple and reliable, suitable for large quantity of production orders, easy to maintain. |

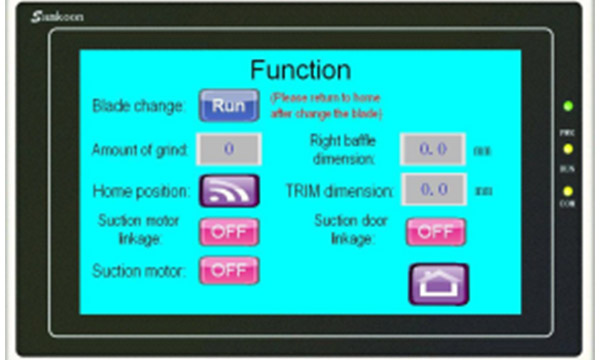

Function

Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

No. | Model | ZBFY-CD2500 | Unit |

1 | Blades & scorer | 4blade 6scorer | / |

2 | Feeder | Auto | / |

3 | Pressure adjustment | Auto | / |

4 | Speed | 160 | m/min |

5 | Max. feeding width | 2500 | mm |

6 | Max. slitting width | 2500 | mm |

7 | Min. slitting width | 200 | mm |

8 | Min. feeding length | 280 | mm |

9 | Min. scoring width | 40x140 | mm |

10 | Feeding thickness | 2-7 | mm |

11 | Air pressure | 0.4 | Mpa |

12 | Main motor power | 5.5 | kw |

13 | Dimension(LxWxH) | 2170x3450x1500 | mm |

14 | Overall net weight | Abt 3800+1500 | kg |

Cardboard ≤ 700gsm

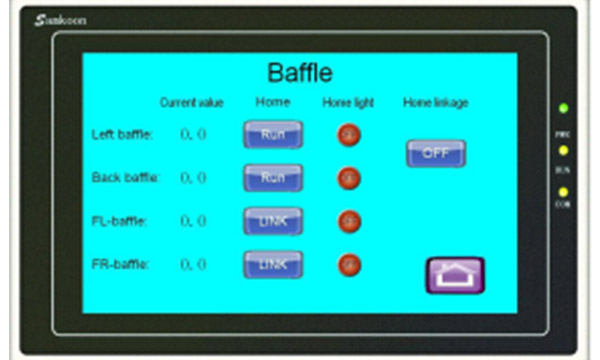

Operation HMI for Auto feeder

Auto Thin Blade Slitter Scorer ZBFY-CD2500

● Auto feeder

● Auto adjusted slitter

● Auto adjusted pre-scorer and scorer

● Auto/manual blade grinder

● Auto adjusted pressure

● Jog function for fine-adjusted

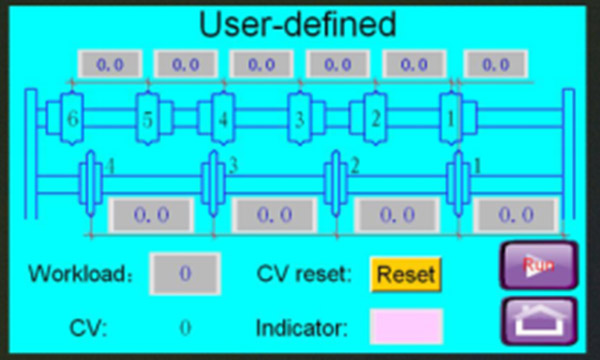

● User-defined function

● Auto counter

● Slitting and scorer Precision ±0.5mm

Operation HMI for Main machine

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

Company Features1. Jingou Packaging Machinery Co., Ltd. holds temporarily a leading position in core cutting machine field.

2. We've been focusing on manufacturing high quality corrugated box making machine for domestic and abroad customers.

3. With the emerging of economic, we put forward the concept of core cutting machine price to be more concentrated on this field. Get info!