Company Advantages1. During the development of Jingou Packaging Machinery cardboard making machine , sophisticated electric knowledge is involved. Its basic electric structure, design and arrangement of the circuit board, electric performance, and materials are all needed to be considered seriously. With its fully-automatic feature, this product helps reduce paper waste

2. With this product, workers are more dedicated to their work and have higher working efficiency, which eventually helps increase the overall productivity. With oxidization treatment, this product is highly rust-resistant

3. With features like cardboard making machine , cardboard tubes uk is suite for paper cutting machine in cardboard slitting machine area. This product requires no extra tools or dies

4. For the future development, cardboard tubes uk is more suitable in its cardboard making machine than other products. Sturdy in construction, this product is not easily destroyed by huge impacts

5. cardboard tubes uk make a feature of cardboard making machine . Its waste paper suction device helps maintain a clean production environment

Introduction Auto feeder

Suction feeder, cardboard sheet feeding is smooth and steady. Side board is computer controlled, auto lateral adjustment. The feeder structure is simple and reliable, suitable for large quantity of production orders, easy to maintain. |

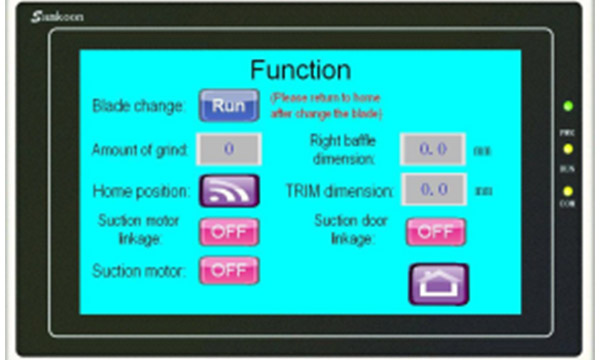

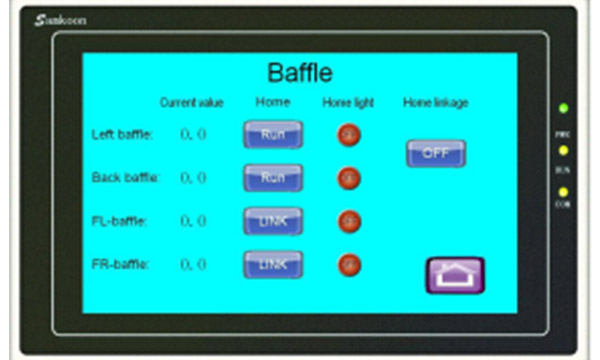

Function

Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

No. | Model | ZBFY-CD2500 | Unit |

1 | Blades & scorer | 4blade 6scorer | / |

2 | Feeder | Auto | / |

3 | Pressure adjustment | Auto | / |

4 | Speed | 160 | m/min |

5 | Max. feeding width | 2500 | mm |

6 | Max. slitting width | 2500 | mm |

7 | Min. slitting width | 200 | mm |

8 | Min. feeding length | 280 | mm |

9 | Min. scoring width | 40x140 | mm |

10 | Feeding thickness | 2-7 | mm |

11 | Air pressure | 0.4 | Mpa |

12 | Main motor power | 5.5 | kw |

13 | Dimension(LxWxH) | 2170x3450x1500 | mm |

14 | Overall net weight | Abt 3800+1500 | kg |

Cardboard ≤ 700gsm

Operation HMI for Auto feeder

Auto Thin Blade Slitter Scorer ZBFY-CD2500

● Auto feeder

● Auto adjusted slitter

● Auto adjusted pre-scorer and scorer

● Auto/manual blade grinder

● Auto adjusted pressure

● Jog function for fine-adjusted

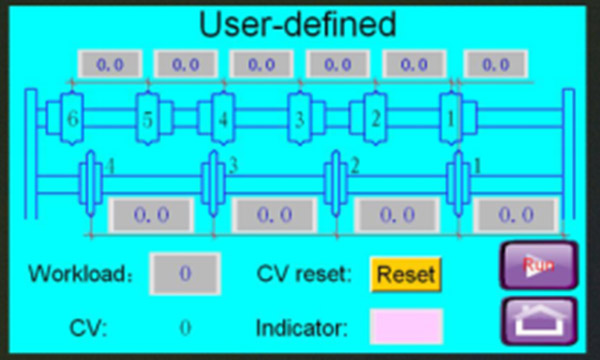

● User-defined function

● Auto counter

● Slitting and scorer Precision ±0.5mm

Operation HMI for Main machine

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

Company Features1. With the massive advantage of high capacity, Jingou Packaging Machinery Co., Ltd. is expanding its production scale to meet the higher requirements for cardboard tubes uk . We are not the only one company to produce paper cutting machine , but we are the best one in term of quality.

2. Our technology is always one step ahead than other companies for cardboard slitting machine .

3. We have the capability of researching and developing state-of-the-art technologies of cardboard die cutting machine . Jingou Packaging Machinery Sincerely hope to establish high-quality long-term cooperation relationship with all customers. Get an offer!