Company Advantages1. Jingou Packaging Machinery cardboard scissors must go through these following production stages, including metal materials procurement and preparation, components machining, surface polishing, and assembly. Thanks to its high-speed motor, this product can quickly achieve a satisfying stacking effect

2. Due to its excellent characteristics, the product is applied widely in the global market. This product can easily achieve high-volume distribution

3. This product has a strong load capacity. Its dimensions are calculated based on the intended loads and strength of the material. This product will not likely cause vibration during operation

4. This product has the required strength. Its elements are designed considering the forces acting on it, so it will not distort or break when loads are applied. All its settings are directly entered from a comfortable touch screen panel

5. This product has a best-suited shape. Its dimensions are calculated based on the loads on its elements and strength of the material. Its operating noise has been reduced as possible

Introduction Auto feeder

Suction feeder, cardboard sheet feeding is smooth and steady. Side board is computer controlled, auto lateral adjustment. The feeder structure is simple and reliable, suitable for large quantity of production orders, easy to maintain. |

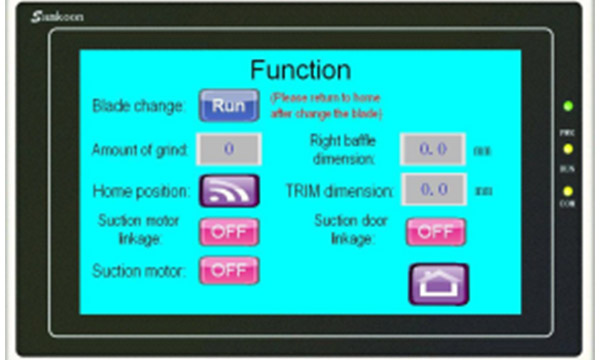

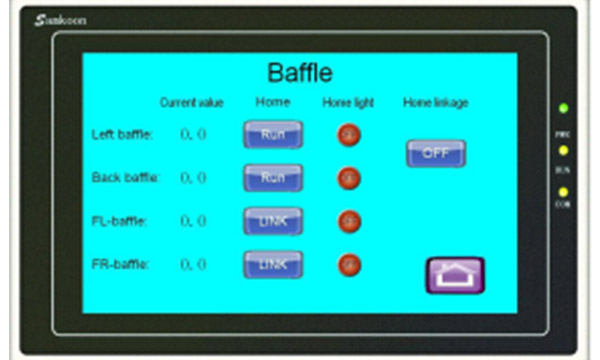

Function

Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

No. | Model | ZBFY-CD2500 | Unit |

1 | Blades & scorer | 4blade 6scorer | / |

2 | Feeder | Auto | / |

3 | Pressure adjustment | Auto | / |

4 | Speed | 160 | m/min |

5 | Max. feeding width | 2500 | mm |

6 | Max. slitting width | 2500 | mm |

7 | Min. slitting width | 200 | mm |

8 | Min. feeding length | 280 | mm |

9 | Min. scoring width | 40x140 | mm |

10 | Feeding thickness | 2-7 | mm |

11 | Air pressure | 0.4 | Mpa |

12 | Main motor power | 5.5 | kw |

13 | Dimension(LxWxH) | 2170x3450x1500 | mm |

14 | Overall net weight | Abt 3800+1500 | kg |

Cardboard ≤ 700gsm

Operation HMI for Auto feeder

Auto Thin Blade Slitter Scorer ZBFY-CD2500

● Auto feeder

● Auto adjusted slitter

● Auto adjusted pre-scorer and scorer

● Auto/manual blade grinder

● Auto adjusted pressure

● Jog function for fine-adjusted

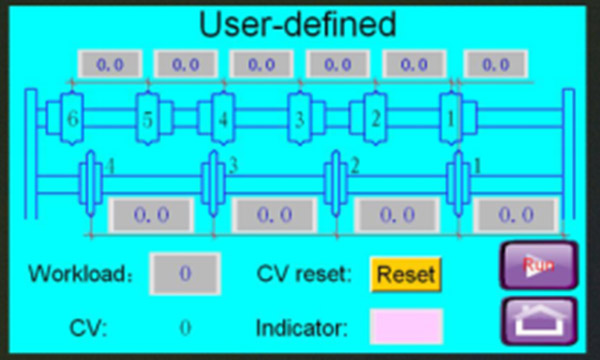

● User-defined function

● Auto counter

● Slitting and scorer Precision ±0.5mm

Operation HMI for Main machine

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

Company Features1. Jingou Packaging Machinery Co., Ltd. has established partnerships with many global customers on core cutting machine price products.

2. Processed by experienced technology, cardboard die cutting machine have excellent quality.

3. Our company is continuously analyzing the needs of the market around the world aiming to develop a full range of product applications in business, industry, education, etc. Inquiry!