Function

Application: for carton & cardboard manufacturer. Advantages: this machine is PLC+HMI control, can finish pre-pressing, slitting, scoring, trimming in one time pass. Simple operation, quick set-up, size change in seconds, greatly shorten set-up time and improve efficiency. Operation: choose box type, input carton info, blades and scorer are ready to produce at the touch of a button. Both skillful operator and newcomer can control it well. Productivity: hundreds of small quantity orders per day. Set up time: 1-30 seconds. Memory: save 300 orders | Manual feeder Auto adjusted slitter Auto adjusted pre-scorer and scorer Auto/manual blade grinder Auto adjusted pressure Jog function for fine-adjusted User-defined function Auto counter Slitting and scorer Precision ±0.5mm |

SPECIFICATIONS

No. | Model | ZBFY-AD2500 | |

1 | Blade/scorer | 4blade 6scorer | 5blade 8scorer |

2 | Feeder | Manual | |

3 | Pressure adjust | Auto | |

4 | Max. speed | 180m/min | |

5 | Max. feeding width | 2600mm | |

6 | Max. slitting width | 2500mm | |

7 | Min. slitting width | 190mm | |

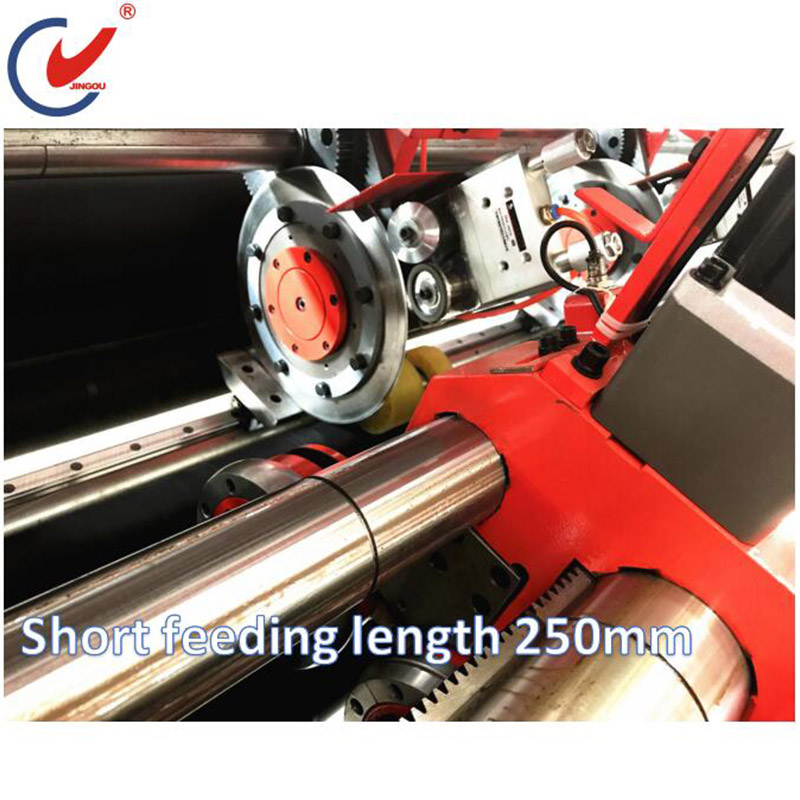

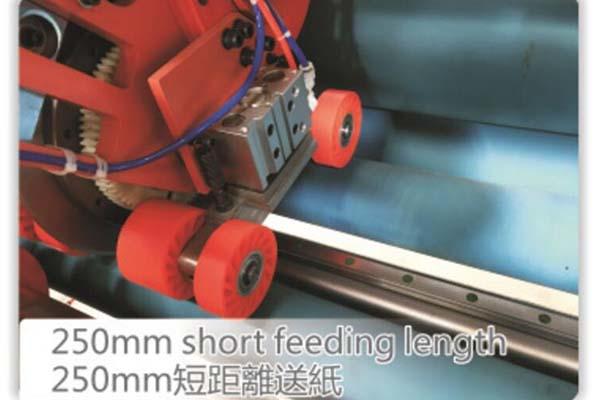

8 | Min. feeding length | 250mm (1for1: 480mm) | |

9 | Min. scoring width | 40x140mm | |

10 | Sheet thickness | 2-7mm | |

11 | Air pressure | 0.4Mpa | |

12 | Main motor power | 4kW | 5.5kW |

13 | Dimension(LxWxH) | 1570x3450x1500mm | |

14 | Overall net weight | 2500kg | 2800kg |

DESCRIBE

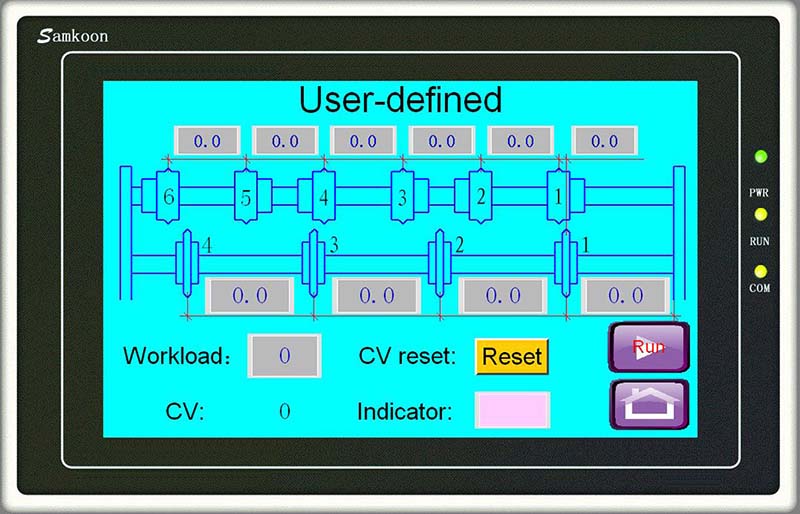

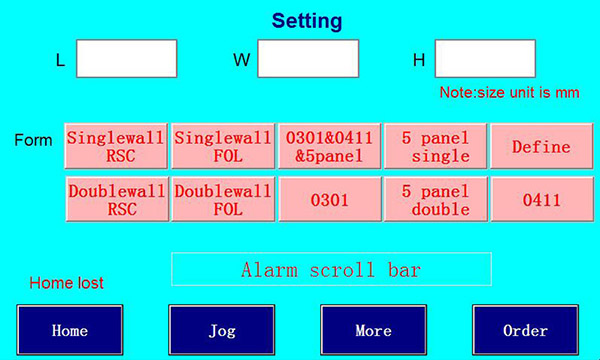

Operation HMI for Main machine

If you have some special work, can use this User-defined function

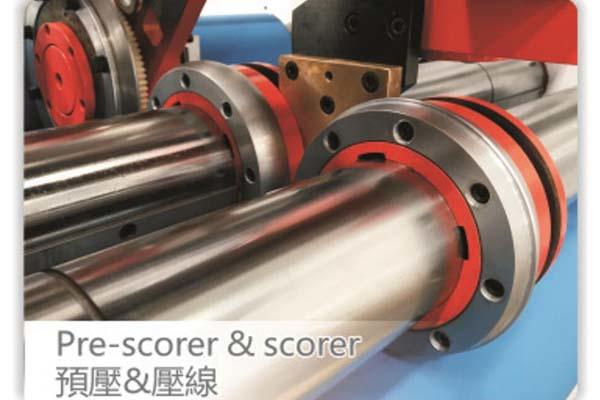

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

After-sales service

● Thanks to developed internet and after-sales network, communication become more and more convenience.

● The reliability of our machines make problem solving much easier, 99% of technical problem can be solved via remote assistance.

● Whenever customer need assistance or ask questions can communicate with the sales staff online, real-time to solve the problem, we are able to provide a full spectrum of services and prompt support.

1. Q: Are you a factory or trading company?

A: We are professional carton machinery manufacturer more than 20 years, is one of biggest factory in North of China. We have exportor license.

2. Q: where is your factory located?

A: Our factory is located in Dongguang County, Hebei Province, North of China .

Near with Beijing (about 1 hours by high speed rail and 1 hour by car), Tianjin (3 hours by train),

convenient transportation.

All our clients from home and aboard, are warmly welcome to visit us!

3. Q: How does your factory do regarding quality control?

A: Quality is priority.

Tongbao always attach great importance to quality controlling from beginning to end.

Most of our machine had gained CE certification.

4. Q: How about Installation and testing

A: If you need us to install and test the machine, we can arrange engineer for you.

5. Q: What is your main product?

A: We are professional in packaging machine more than 20 years.

Our main product: 2/3/5 layer corrugated paperboard production line(Including mill roll stand, pre-heater,single facer, conveyor bridge, gluing machine, double facer, slitter scorer,cut-off, conveyer and stacker etc.) automatic carton printing slotting and die-cutting machine, folder gluer machine, Die cutting and creasing machine, lamination machineStitching machine etc.

If the machine has quality problem in one year,we will offer the spare part free of charge,but quick-wear part not included,such as rubber roller.if the buyer need the seller to install and erect the machine,the buyer must be responsble siva fees and round trip flight tickets and accommodation and food of the work,and should pay 60 usd per person per day.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved