Company Advantages1. During the production of Jingou Packaging Machinery box making machine , The overall light quality such as color rendering, color temperature, and the efficiency of the light source is obviously enhanced. This product will not likely cause vibration during operation

2. Less time and effort are needed to maintain this product over the years, therefore one can save energy and costs. This product is perfectly suitable for the corrugated paper packaging industry

3. The product has excellent impact toughness. Its heavy metal materials are able to resist impulse load and shock load without cracking. It can speed up the corrugated box production, reducing the reliance on packaging labors

4. The product is not easily deformed due to large temperature difference. Its heavy-duty components and parts are designed to withstand tremendous abuse in a constantly changing environment. It has a simple structure that allows operators to work more relaxingly

5. The product is safe to use. Those parts that are easily tossed out are equipped with safety devices such as a shield or protective screening. Equipped with an automatic board feeder, this product features high efficiency

Introduction Auto feeder

Suction feeder, cardboard sheet feeding is smooth and steady. Side board is computer controlled, auto lateral adjustment. The feeder structure is simple and reliable, suitable for large quantity of production orders, easy to maintain. |

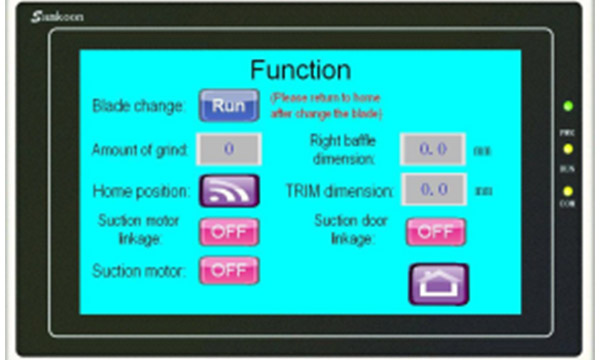

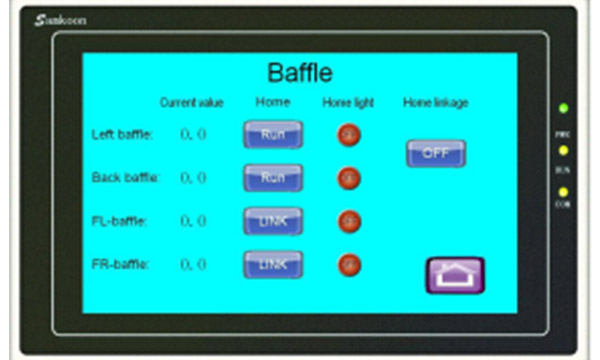

Function

Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

No. | Model | ZBFY-CD2500 | Unit |

1 | Blades & scorer | 4blade 6scorer | / |

2 | Feeder | Auto | / |

3 | Pressure adjustment | Auto | / |

4 | Speed | 160 | m/min |

5 | Max. feeding width | 2500 | mm |

6 | Max. slitting width | 2500 | mm |

7 | Min. slitting width | 200 | mm |

8 | Min. feeding length | 280 | mm |

9 | Min. scoring width | 40x140 | mm |

10 | Feeding thickness | 2-7 | mm |

11 | Air pressure | 0.4 | Mpa |

12 | Main motor power | 5.5 | kw |

13 | Dimension(LxWxH) | 2170x3450x1500 | mm |

14 | Overall net weight | Abt 3800+1500 | kg |

Cardboard ≤ 700gsm

Operation HMI for Auto feeder

Auto Thin Blade Slitter Scorer ZBFY-CD2500

● Auto feeder

● Auto adjusted slitter

● Auto adjusted pre-scorer and scorer

● Auto/manual blade grinder

● Auto adjusted pressure

● Jog function for fine-adjusted

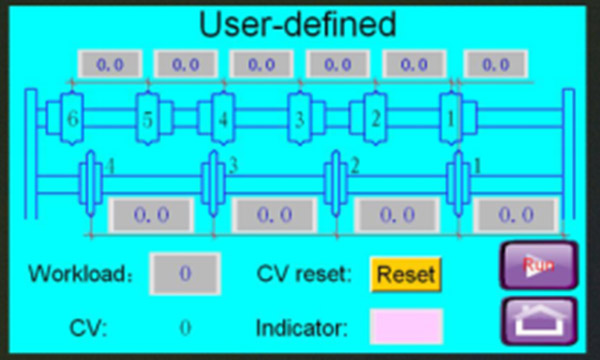

● User-defined function

● Auto counter

● Slitting and scorer Precision ±0.5mm

Operation HMI for Main machine

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

Company Features1. With advanced technology and sophisticated equipment, Jingou Packaging Machinery Co., Ltd. fully controls the quality of its products.

2. Our business is devoted to sustainability. In compliance with our waste management hierarchy minimize waste creation and regain any waste that's generated at the greatest potential price.