Company Advantages1. dremel cutting tool takes on by elegant shape to meet high demands. All its settings are directly entered from a comfortable touch screen panel

2. After times of wear, this product is guaranteed that it will be not subject to problems like color fading and paint flaking off. This product is highly adaptable to paper with different thicknesses

3. Its luster is related to the indices of absorption and refraction and the amount of dispersion from the crystal lattice, as well as the texture of its exposed surface. Built-in waste separation function, this product meets the needs of sustainability practices

4. Other features that are characteristic to this mattress include its allergy-free fabrics. The materials and the dye are totally non-toxic and will not cause allergies. This product gives companies the ability to reliably package and ship right-sized orders

5. It has the characteristic of burst resistance. Its strength parameters are carefully calculated and its bursting strength is verified with the typical toughness test. With the microcomputer control, this product is less likely to fail

Introduction Auto feeder

Suction feeder, cardboard sheet feeding is smooth and steady. Side board is computer controlled, auto lateral adjustment. The feeder structure is simple and reliable, suitable for large quantity of production orders, easy to maintain. |

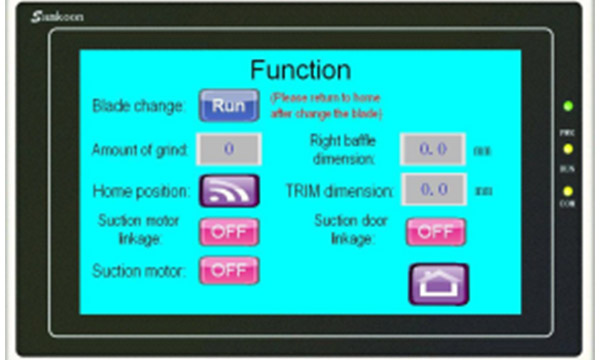

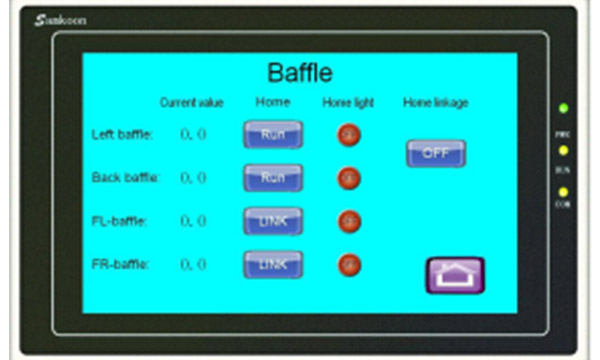

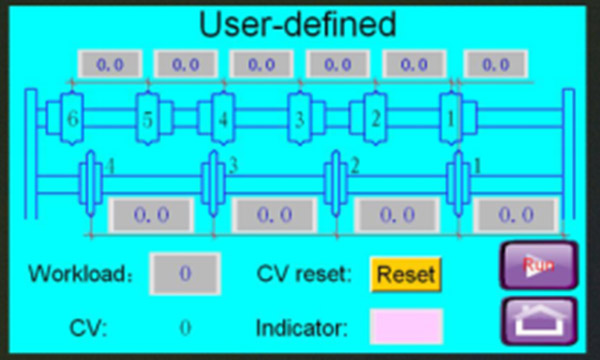

Function

Main Function: Auto feed, slot, score, angle cut and trim all in one. All tools are controlled through HMI touch screen. Auto/manual blade grinder Auto adjusted Servo vacuum auto feeder system. Extended arms in working table for oversize sheets. Baffle, slot knives, crease pressure are individual drive. Special H slot structure, can do small, medium and oversize carton. Standard slot knives size: 7mm width x 500mm length, or customized. Emergency stop switch in operation panel and back side. |

No. | Model | ZBFY-CD2500 | Unit |

1 | Blades & scorer | 4blade 6scorer | / |

2 | Feeder | Auto | / |

3 | Pressure adjustment | Auto | / |

4 | Speed | 160 | m/min |

5 | Max. feeding width | 2500 | mm |

6 | Max. slitting width | 2500 | mm |

7 | Min. slitting width | 200 | mm |

8 | Min. feeding length | 280 | mm |

9 | Min. scoring width | 40x140 | mm |

10 | Feeding thickness | 2-7 | mm |

11 | Air pressure | 0.4 | Mpa |

12 | Main motor power | 5.5 | kw |

13 | Dimension(LxWxH) | 2170x3450x1500 | mm |

14 | Overall net weight | Abt 3800+1500 | kg |

Cardboard ≤ 700gsm

Operation HMI for Auto feeder

Auto Thin Blade Slitter Scorer ZBFY-CD2500

● Auto feeder

● Auto adjusted slitter

● Auto adjusted pre-scorer and scorer

● Auto/manual blade grinder

● Auto adjusted pressure

● Jog function for fine-adjusted

● User-defined function

● Auto counter

● Slitting and scorer Precision ±0.5mm

Operation HMI for Main machine

Slitting with sun wheel, more stable, pre-pressing wheels and scorer move together.

Company Features1. Jingou Packaging Machinery Co., Ltd. has always been focusing on the R&D and production of dremel cutting tool . We have employed a professional manufacturing team. They have long term experience in solving difficult manufacturing challenges. Their technology competence is far beyond average.

2. Our company has teams of dedicated product developers. They are able to discover the exact needs of customers while balancing engineering and manufacturing constraints to deliver innovative solutions.

3. Our company has gathered a group of experts. With considerable expertise, these experts can always help customers solve challenges, and work alongside customers to offer insights that matter to the project. Our company has a mission of Always Advancing to Protect What's Important and is committed to building a more sustainable future. Our No. 1 priority is safety and with continuous improvement in our safety practices, we have reduced the incident rate far below the industry average.